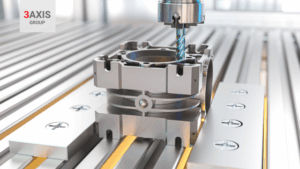

In the world of CNC machining, understanding the differences between vertical and horizontal CNC milling machines can make a significant impact on productivity, quality, and overall project efficiency. Each type of machine offers unique advantages and is suited to specific applications.

This guide will help clarify these differences, allowing you to make the best choice for your manufacturing needs.

Key Features of Vertical CNC Milling Machines

Vertical CNC milling machines are widely recognized for their versatility, making them ideal for various tasks, from prototype creation to high-volume production. Below, we’ll dive into what makes vertical mills a popular choice across industries.

Structure and Design

Vertical CNC milling machines feature a vertically oriented spindle, meaning that the cutting tool moves up and down. This vertical orientation allows for straightforward setups, as operators can easily load and position workpieces.

Vertical mills are typically more compact than horizontal models, making them a practical option for shops with limited floor space.

Additionally, vertical mills offer high visibility, allowing operators to observe the machining process more closely, which can lead to improved precision and immediate adjustments when necessary.

Common Applications for Vertical Milling

Due to their design, vertical CNC milling machines are particularly suited to tasks requiring precision on relatively small to medium-sized components. They are commonly used for:

- Prototyping – Quick setups and ease of use make vertical mills ideal for developing prototypes.

- Die sinking – Precision in vertical orientation benefits tasks like die sinking, where accurate material removal is crucial.

- Complex 3D parts – These machines excel in creating complex geometries on components for various industries, including automotive, aerospace, and medical.

With their accessibility and flexibility, vertical CNC milling machines are a staple for any machining shop focused on precision work.

Key Features of Horizontal CNC Milling Machines

Horizontal CNC milling machines offer a different set of benefits, specifically geared toward larger-scale production and heavy-duty machining tasks. Let’s explore what makes these machines distinctive and advantageous for demanding machining needs.

Structure and Design

In horizontal CNC milling machines, the spindle is oriented horizontally. This setup allows for the use of longer cutting tools, which can cover a larger area on the workpiece in a single pass. Horizontal mills also feature tombstone setups, where multiple parts can be mounted on each side of a fixture, allowing for continuous production.

This design can significantly enhance productivity, as operators can load multiple workpieces for machining in a single setup, reducing downtime.

Common Applications for Horizontal Milling

Horizontal milling machines are particularly well-suited for tasks that involve bulk material removal and are widely used for:

- Heavy-duty cutting – With more power and rigidity, horizontal mills excel at removing large amounts of material, making them suitable for roughing and bulk material removal.

- Large components – For industries like aerospace and energy, where components tend to be larger, the stability and extended tool reach of horizontal mills are critical advantages.

- Continuous or high-volume production – The tombstone setup allows for simultaneous machining of multiple parts, making it ideal for manufacturers focused on efficiency and high-volume output.

In conclusion, the differences between vertical and horizontal CNC milling machines lie in their structure, design, and ideal applications. While vertical CNC milling machines are versatile, accessible, and suitable for precise tasks, horizontal machines excel in handling bulk material removal, high-volume production, and larger workpieces.

Each type has its strengths, and understanding them can help businesses make more informed purchasing decisions.

If you enjoyed this article, you might also be interested in learning: What Can Be Done with an Industrial Milling Machine?

Looking to find the right CNC milling machine for your specific needs? Browse our extensive catalog of both vertical and horizontal CNC milling machines to discover the ideal fit for your workshop.