The first thing you need to know about a milling machines is that it is an indispensable tool in the world of industrial machining, enabling precise and efficient material shaping.

Whether you are new to machining or looking to expand your understanding, this guide covers all the essential details about milling machines. From their types and uses to factors to consider when buying one, we have you covered.

Discover Everything You Need to Know About Milling Machines

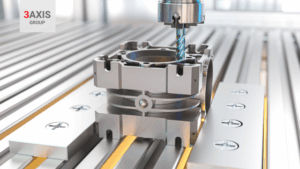

A milling machine is a versatile tool used in the manufacturing industry to shape solid materials such as metal, wood, and plastic. It operates by rotating a cutting tool to remove material from the workpiece, achieving the desired shape and dimensions. Milling machines are crucial for industries like automotive, aerospace, and construction due to their ability to produce highly accurate components.

Types of Milling Machines

Milling machines come in various types, each designed to perform specific tasks efficiently. Understanding the different types helps in selecting the right machine for your business needs.

Horizontal & Vertical Milling Machines

The two most common types of milling machines are horizontal and vertical CNC milling machines. A vertical CNC milling machine has a vertically oriented spindle, making it ideal for tasks that require precision in intricate designs. Horizontal milling machines, on the other hand, have a horizontally aligned spindle, allowing for heavy-duty cutting and material removal. Each type has unique advantages depending on the project requirements.

Plain Milling Machine

Plain milling machines, also known as horizontal mills, are primarily used for surface milling and cutting. These machines are straightforward in design and are best suited for simpler operations. They consist of a worktable, spindle, and cutting tool, offering reliable performance for basic machining tasks.

Mechanically Controlled Milling Machine

Mechanically controlled milling machines operate with mechanical levers and handles, offering a manual approach to machining. While they may lack the advanced features of CNC machines, they are excellent for small-scale operations and prototyping. These machines allow skilled operators to achieve exceptional precision with their hands-on control.

To Know About a Milling Machines and How to Use Them for Perfect Accuracy?

Operating a milling machine requires proper technique and attention to detail to ensure precise results. Follow these steps to use a milling machine effectively:

- Set Up the Workpiece: Secure the material on the worktable using clamps or a vice to prevent movement during machining.

- Choose the Right Tool: Select the appropriate cutting tool based on the material and desired outcome.

- Adjust Machine Settings: Set the spindle speed, feed rate, and depth of cut according to the material and tool specifications.

- Perform Test Cuts: Begin with a light test cut to confirm the settings before proceeding with the full operation.

- Monitor the Process: Continuously monitor the cutting process and make adjustments as needed to maintain accuracy.

- Inspect the Workpiece: After machining, use measuring tools to verify the dimensions and finish of the workpiece.

Factors to be Considered While Buying a Milling Machine

Investing in a milling machine is a significant decision for any business. Here are the key factors to consider:

- Machine Type: Decide between horizontal, vertical, or plain milling machines based on your production needs.

- Precision Requirements: Evaluate the machine’s accuracy and ability to meet your specific tolerances.

- Machine Size: Consider the size of the milling machine and its compatibility with your workspace.

- Power and Speed: Check the machine’s power rating and speed ranges to ensure it can handle your materials.

- CNC Capabilities: If automation is a priority, opt for a vertical CNC milling machine with advanced programming features.

- Durability: Look for machines built with high-quality materials to ensure longevity and reliability.

- Cost: Balance your budget with the features and capabilities of the milling machine to make a cost-effective purchase.

Do you want to know more? You may also be interested in articles such as Differences Between Vertical and Horizontal CNC Milling Machines.

Milling machines are essential tools for precise material shaping in various industries. Understanding their types, uses, and buying considerations ensures you make informed decisions for your business.

So, are you ready to elevate your machining processes? Visit our website to explore our range of milling machines and find the perfect fit for your needs. Let us help you achieve unmatched precision and performance in your projects!