Machine sold

Besides, we not only have the best prices in the market, we also offer you the possibility of financing the purchase to facilitate access to top quality machines at an affordable cost.

It is about important investments and that is why we are clear with a 100% safe machinery purchase and sale process, in order that you have all the necessary information to buy such a product.

To avoid that you have to travel, we take care of the transport and shipment of the purchase to your place of work. We collaborate with companies specialised in this type of orders and we can both, sell at source or turnkey.

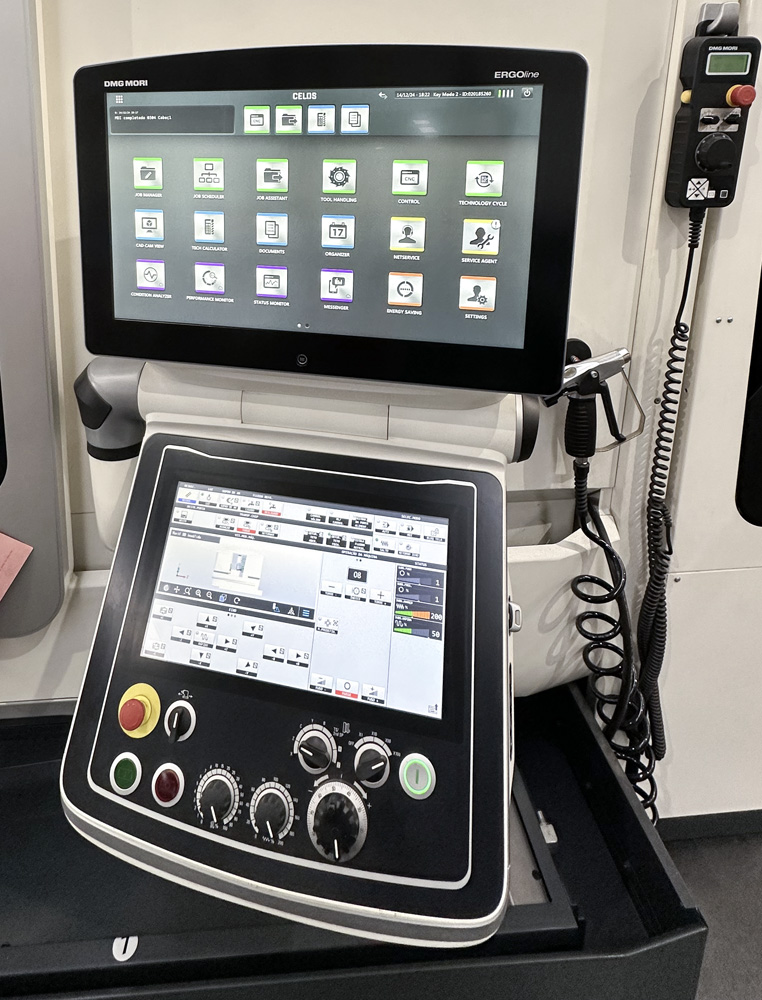

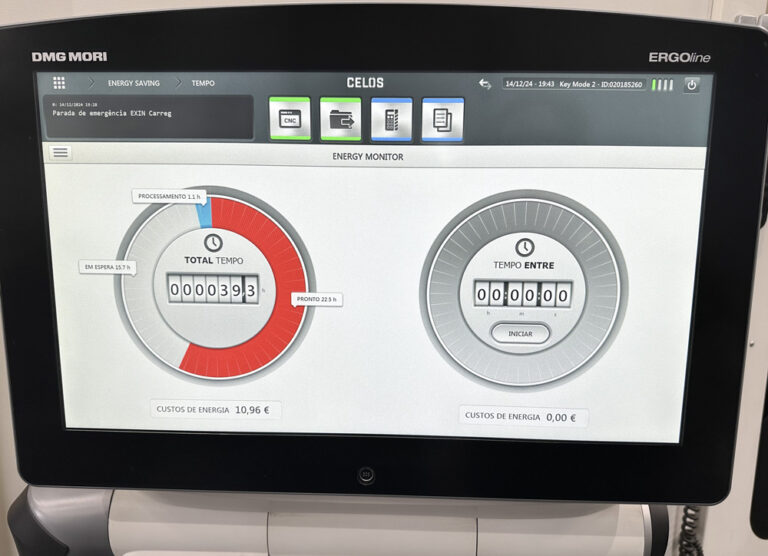

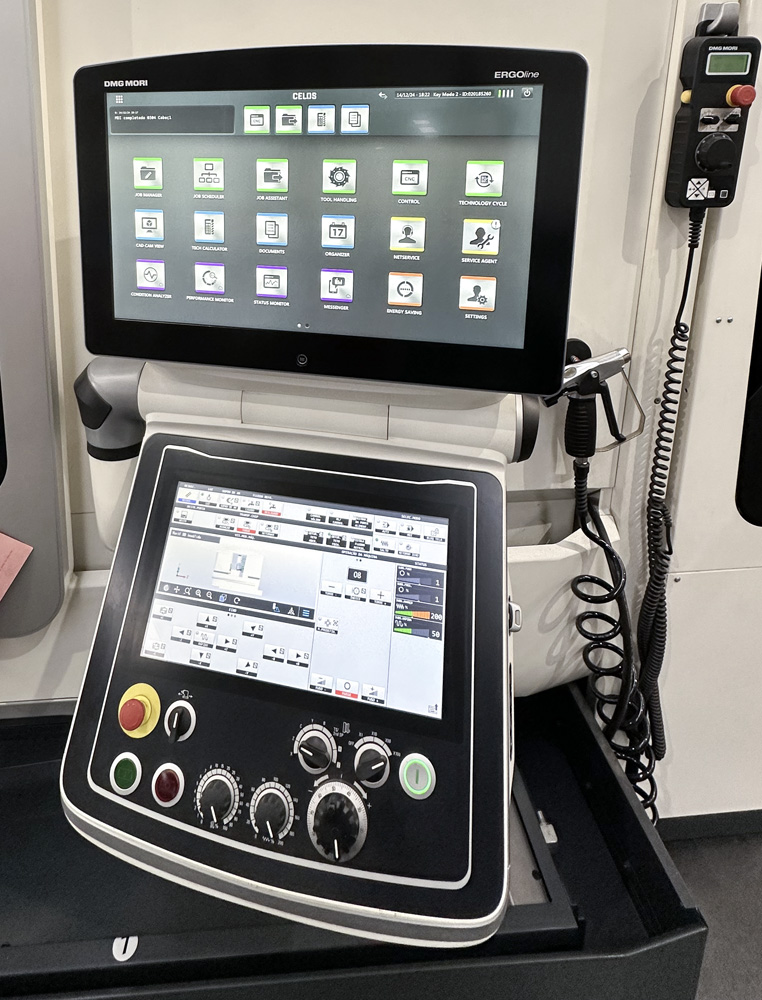

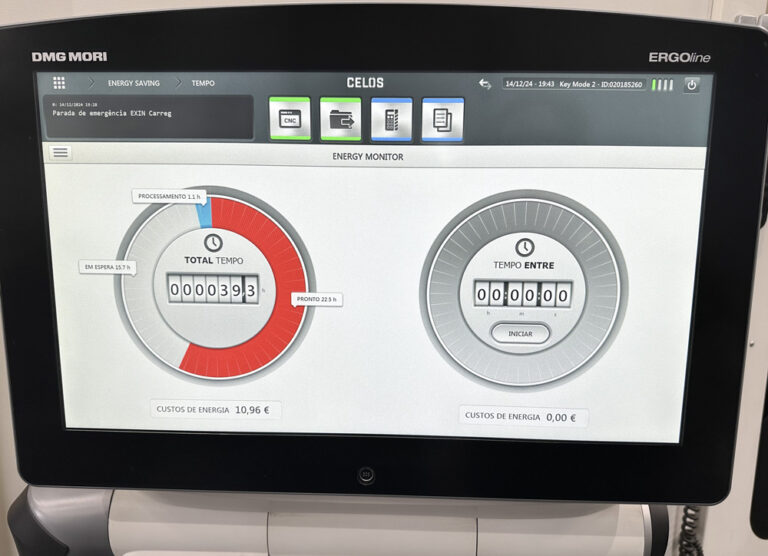

CNC controller: Mitsubishi M730UM (CELOS – ERGOline Touch)

Capacity

X-axis travel mm: 260

Y-axis travel mm: ±50

Z-axis travel mm: 795

Turning length mm: 705

Max. turning diameter mm: ø: 366

Swing over bed mm: ø: 920

Swing over cross-slide mm: 740

Bar work capacity mm: 80

Upper turret

Number of tool slots St .: 12

Speed driven tools RPM: 10.000

Drive power driven tools kW: 5.5/4.9/4.2 (3 min/5 min/cont)

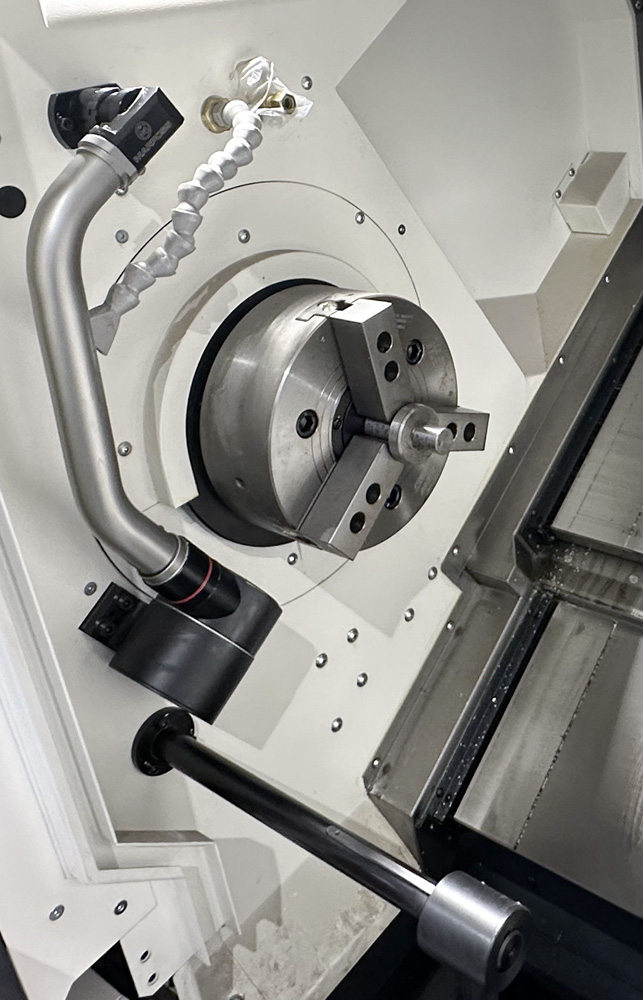

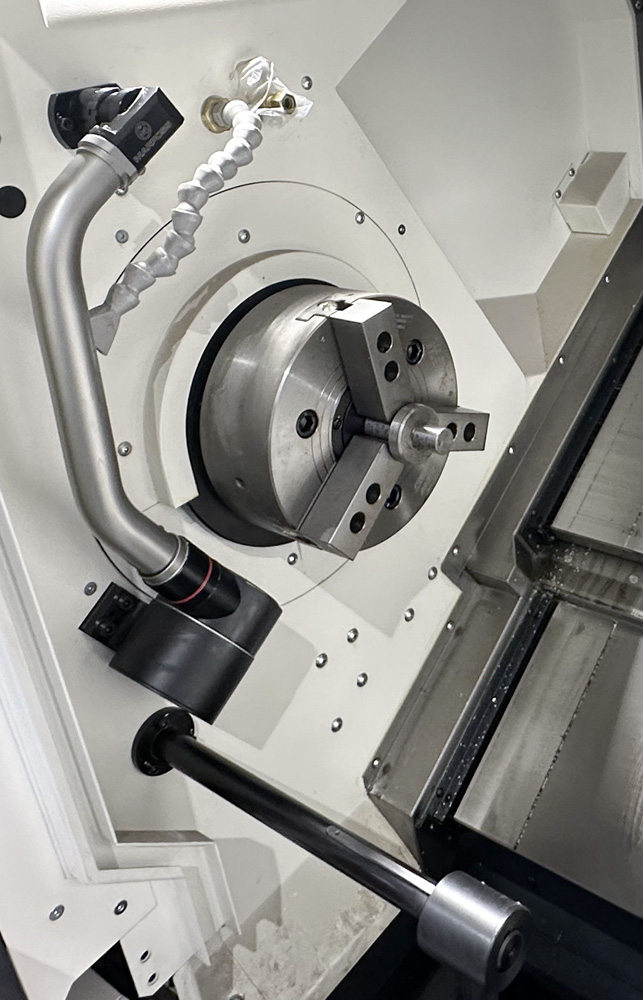

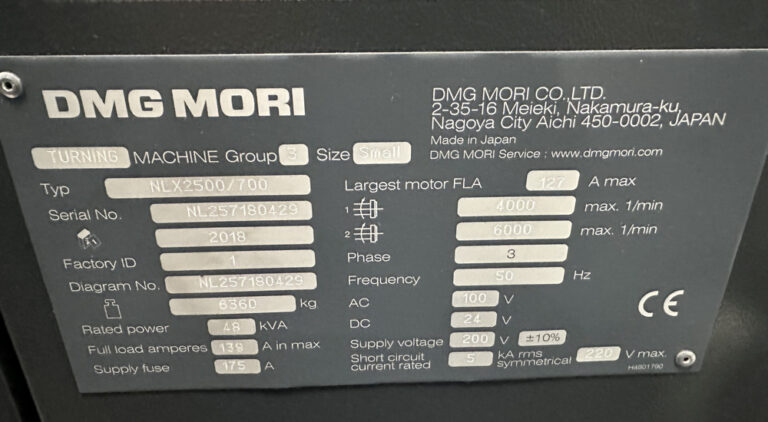

Main spindle

Speed spindle rpm: 4.000

Drive power spindle kW: 18.5/18.5/15 (25%ED/50%ED/cont)

Chuck type: Hollow chuck (10″)

Manufacturer: KITAGAWA

Spindle nose: JIS A2-8

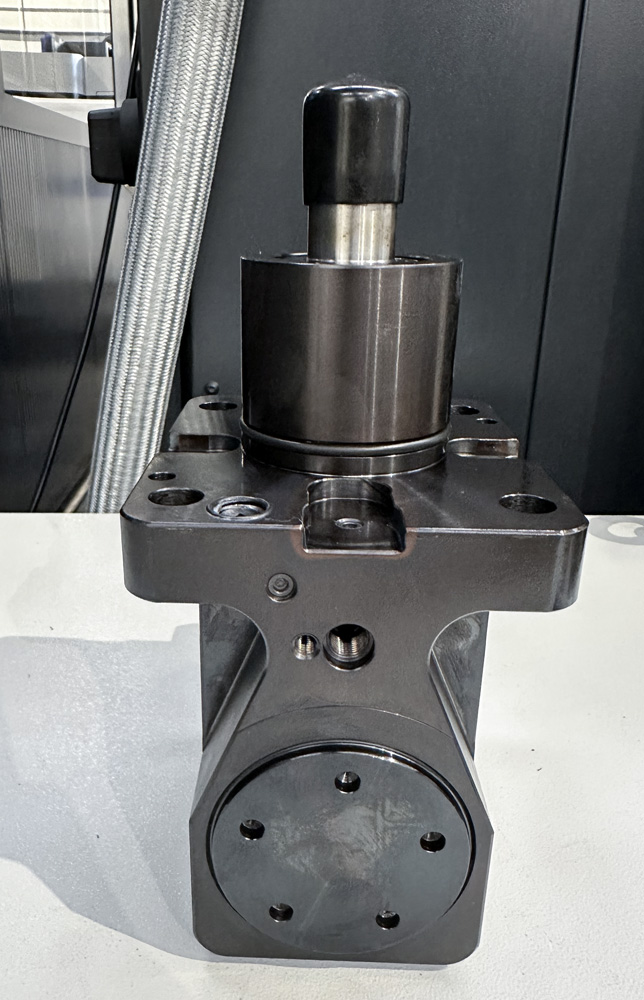

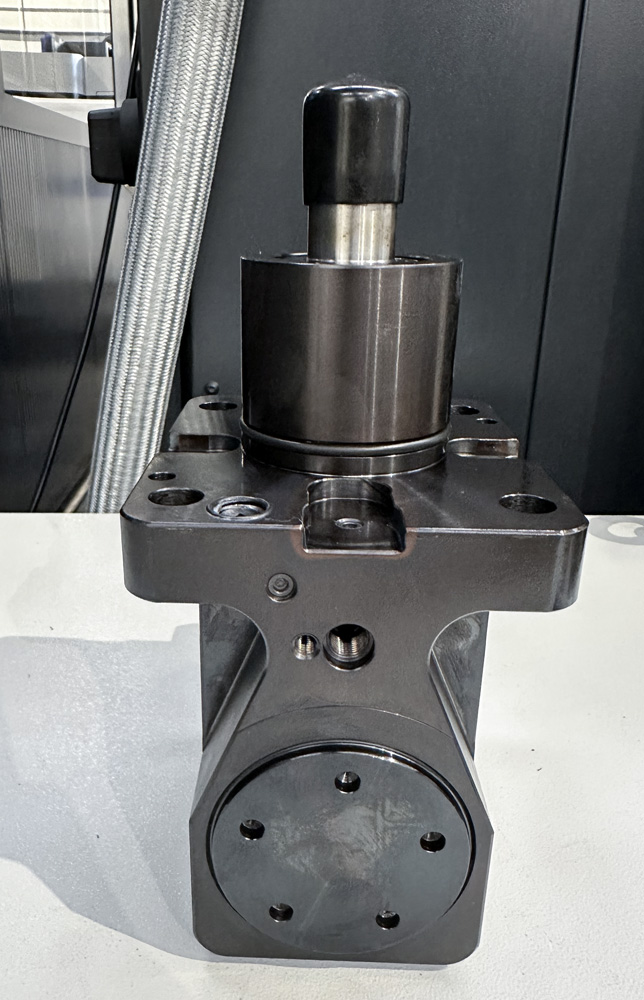

Counter spindle

Speed spindle rpm: 6.000

Drive power spindle kW: 11/7.5 (25%ED/cont)

Spindle bore mm: KITAGAWA

Manufacturer: Hollow chuck (6″)

Spindle nose: JIS A2-5

Counter spindle travel mm: 734

Coolant system

Tank capacity liter: 366

Equipment

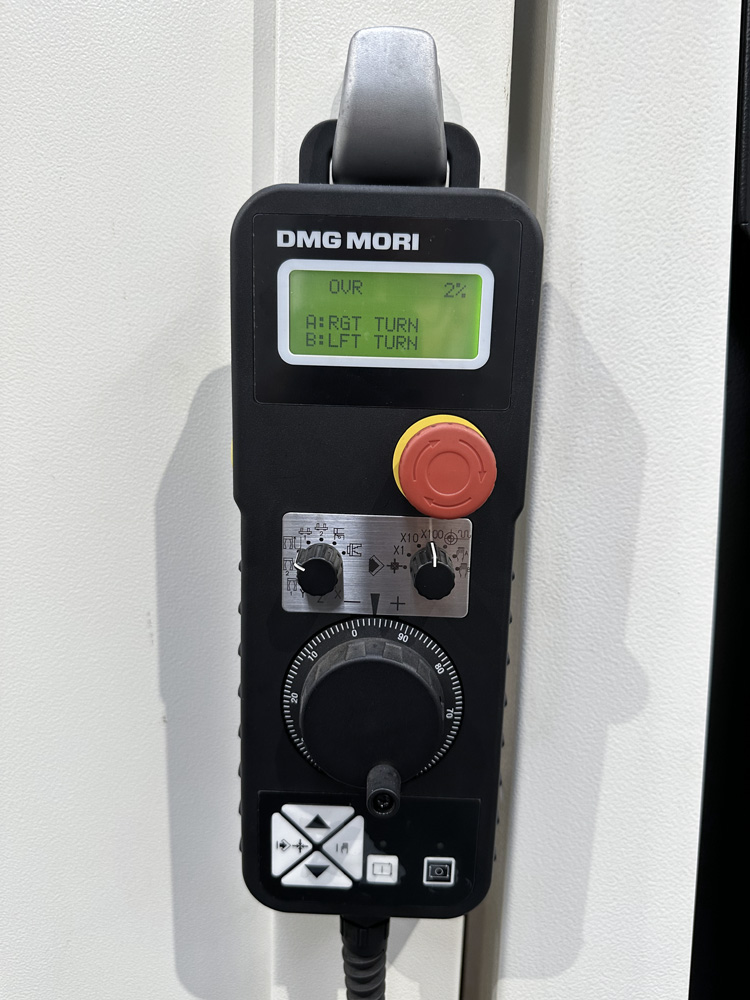

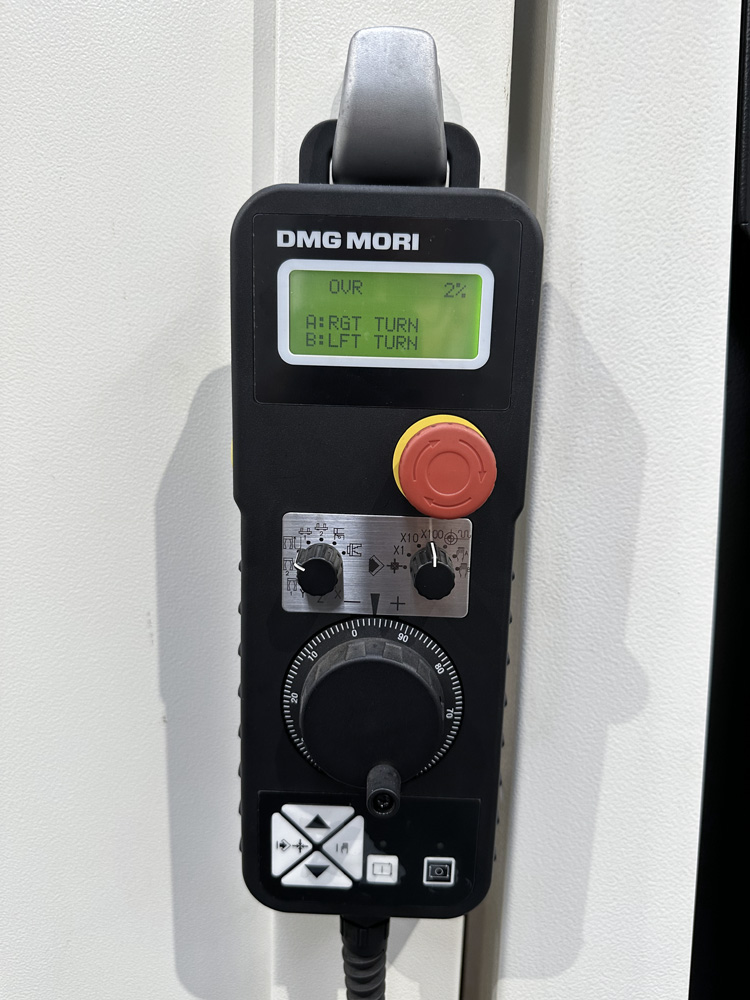

Electronic Handwheel

Chip conveyor

Signal lamp

High pressure pump

Chuck foot switch (double) for main and counter spindle

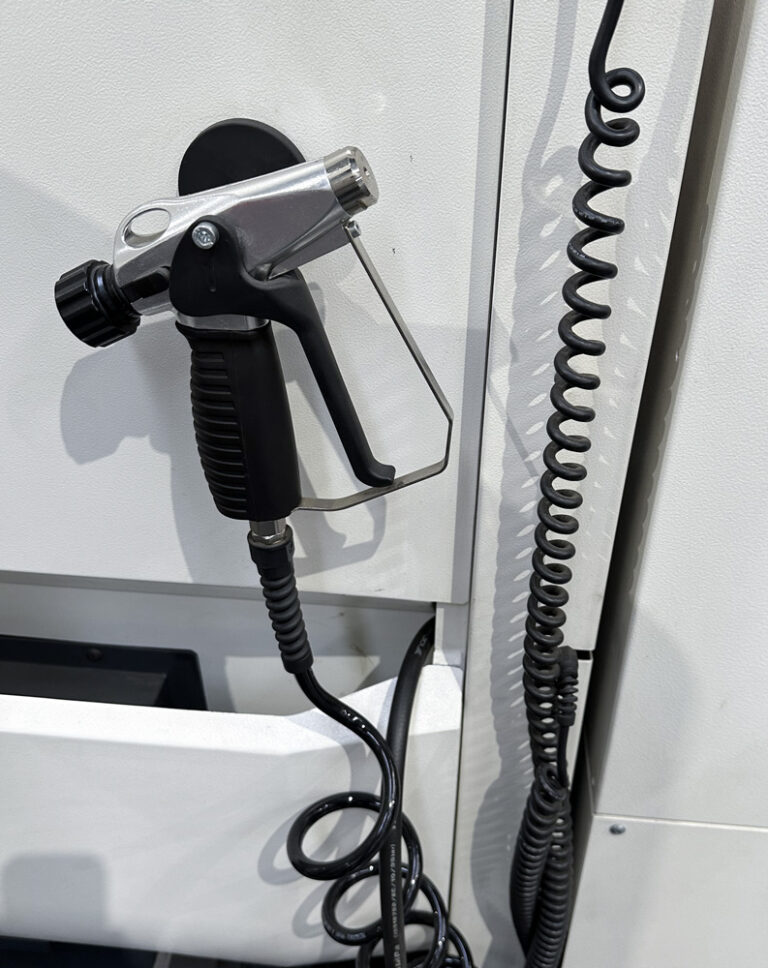

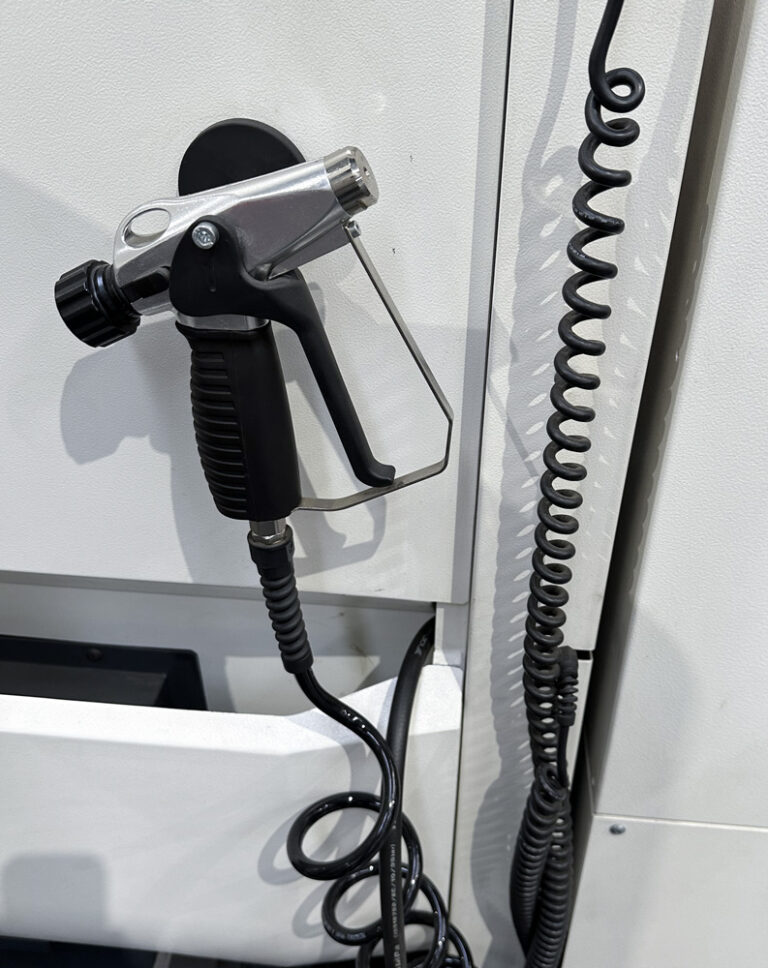

Coolant gun

Interface for Bar feeder

Oil skimmer

Measuring probe

2 + 2 rotary tools axial included

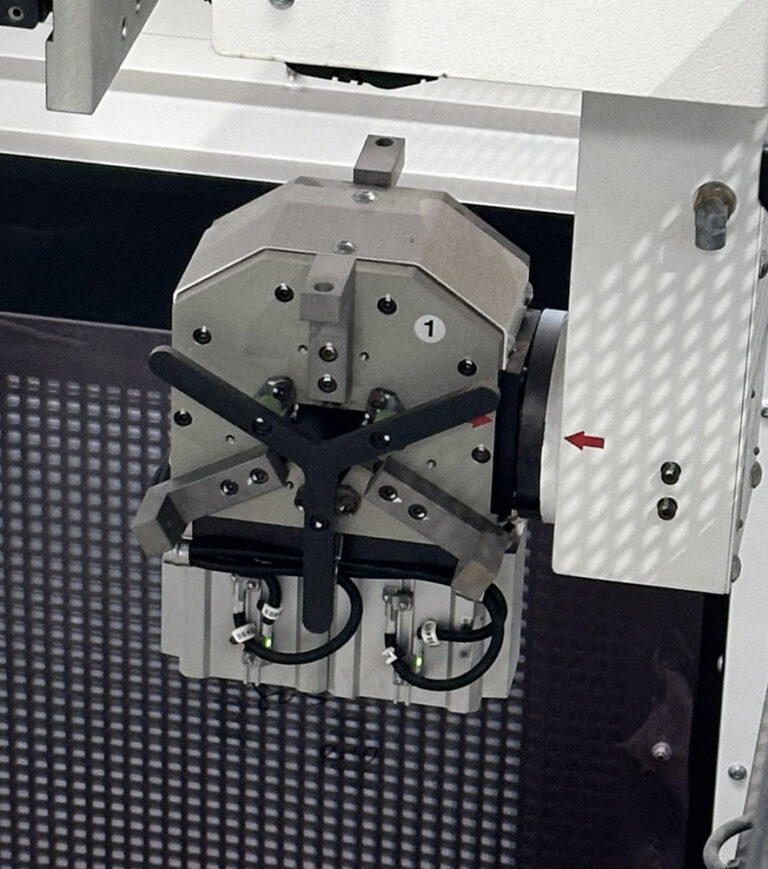

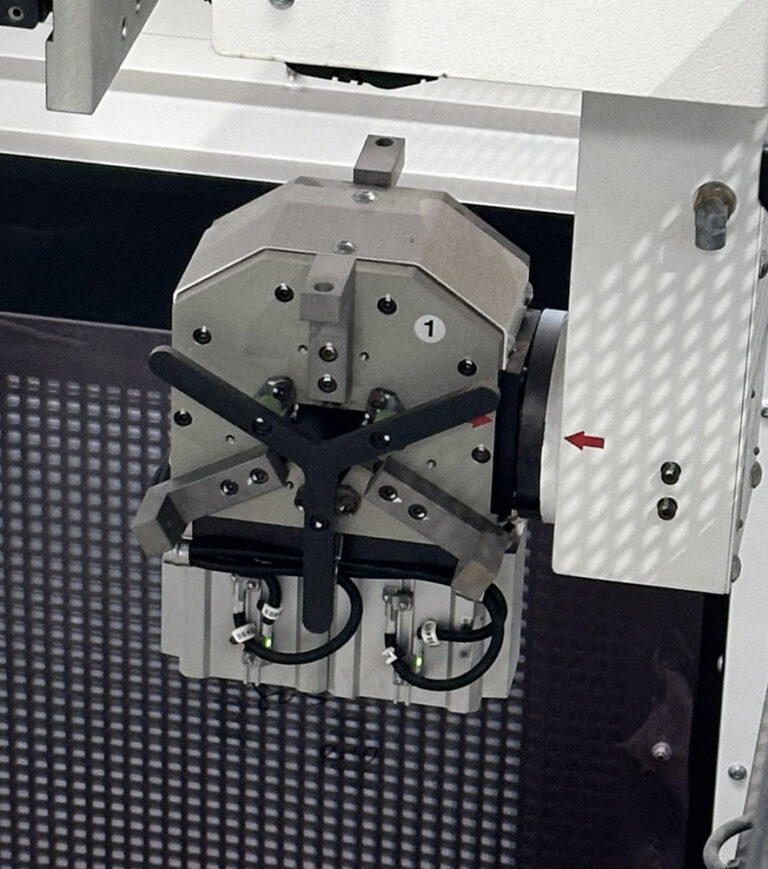

Gantry loader LG-10 AII

Manual In-Machine tool presetter

Standard fixed tools included

Working time hours

Under power: 0 (brand new machine)

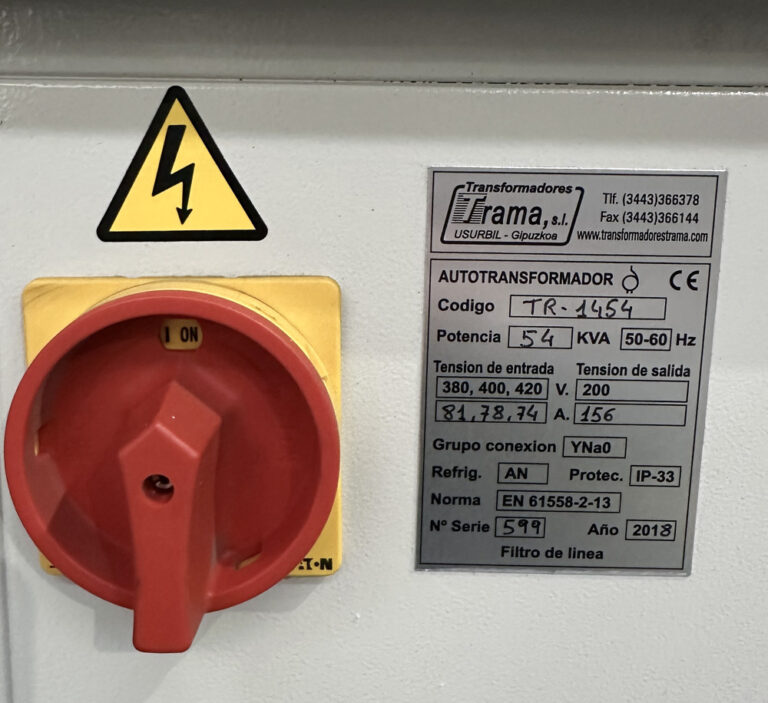

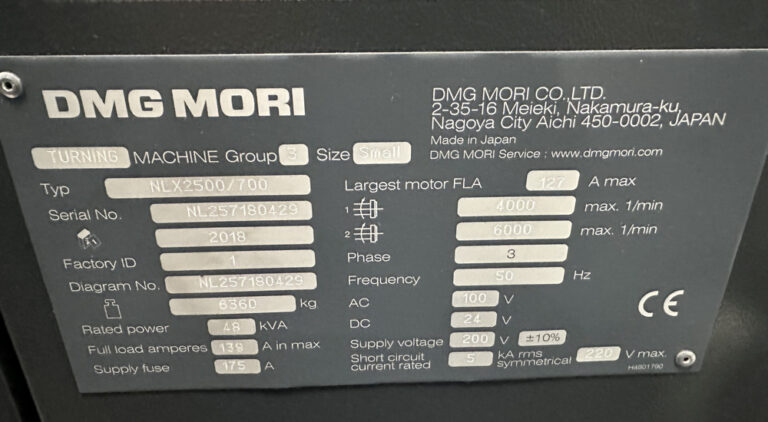

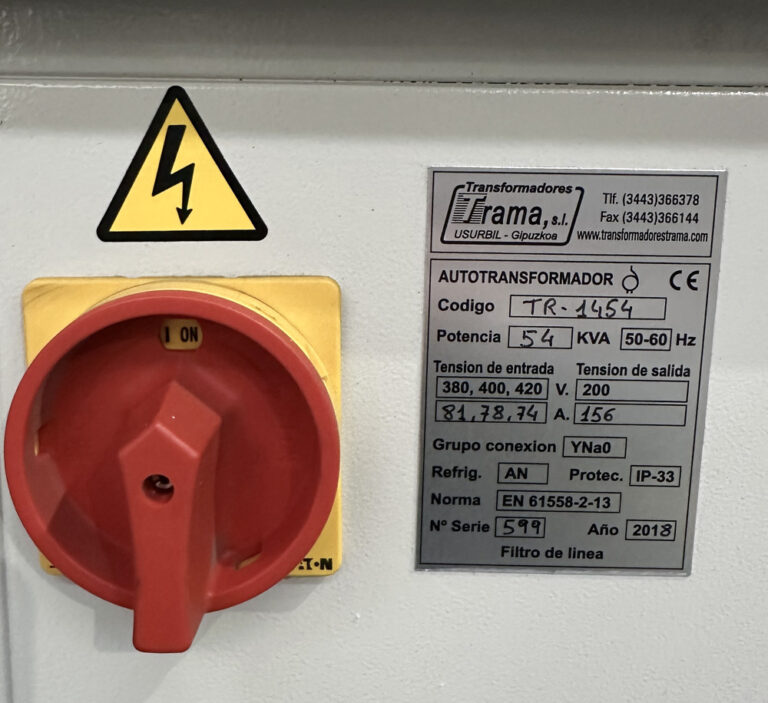

Potencial nominal kVA: 48

Spnidle: 0 (brand new machine)

Basic machine dimensions / weight

Length mm: 3.981

Width mm: 2.025

Height mm: 2.200

Weight kg: 6.360

董雁冰

CEO

Cillian Weber

CEO

DMG Mori

Portugal

2018

DMG Mori

Portugal

2018

CNC controller: Mitsubishi M730UM (CELOS – ERGOline Touch)

Capacity

X-axis travel mm: 260

Y-axis travel mm: ±50

Z-axis travel mm: 795

Turning length mm: 705

Max. turning diameter mm: ø: 366

Swing over bed mm: ø: 920

Swing over cross-slide mm: 740

Bar work capacity mm: 80

Upper turret

Number of tool slots St .: 12

Speed driven tools RPM: 10.000

Drive power driven tools kW: 5.5/4.9/4.2 (3 min/5 min/cont)

Main spindle

Speed spindle rpm: 4.000

Drive power spindle kW: 18.5/18.5/15 (25%ED/50%ED/cont)

Chuck type: Hollow chuck (10″)

Manufacturer: KITAGAWA

Spindle nose: JIS A2-8

Counter spindle

Speed spindle rpm: 6.000

Drive power spindle kW: 11/7.5 (25%ED/cont)

Spindle bore mm: KITAGAWA

Manufacturer: Hollow chuck (6″)

Spindle nose: JIS A2-5

Counter spindle travel mm: 734

Coolant system

Tank capacity liter: 366

Equipment

Electronic Handwheel

Chip conveyor

Signal lamp

High pressure pump

Chuck foot switch (double) for main and counter spindle

Coolant gun

Interface for Bar feeder

Oil skimmer

Measuring probe

2 + 2 rotary tools axial included

Gantry loader LG-10 AII

Manual In-Machine tool presetter

Standard fixed tools included

Working time hours

Under power: 0 (brand new machine)

Potencial nominal kVA: 48

Spnidle: 0 (brand new machine)

Basic machine dimensions / weight

Length mm: 3.981

Width mm: 2.025

Height mm: 2.200

Weight kg: 6.360

Request your quote

Sales Department

Besides, we not only have the best prices in the market, we also offer you the possibility of financing access to top quality machines at an affordable cost.

It is about important investments and that is why we are clear with a 100% safe machinery purchase and sales process, in order that you have all the necessary information to buy such a product.

To avoid that you have to travel, we take care of the transport and shipment of the purchase to your place of work. We collaborate with companies specialised in this type of orders and we can both, sell at source and turnkey.

董雁冰

CEO

Cillian Weber

CEO