Machine sold

Besides, we not only have the best prices in the market, we also offer you the possibility of financing the purchase to facilitate access to top quality machines at an affordable cost.

It is about important investments and that is why we are clear with a 100% safe machinery purchase and sale process, in order that you have all the necessary information to buy such a product.

To avoid that you have to travel, we take care of the transport and shipment of the purchase to your place of work. We collaborate with companies specialised in this type of orders and we can both, sell at source or turnkey.

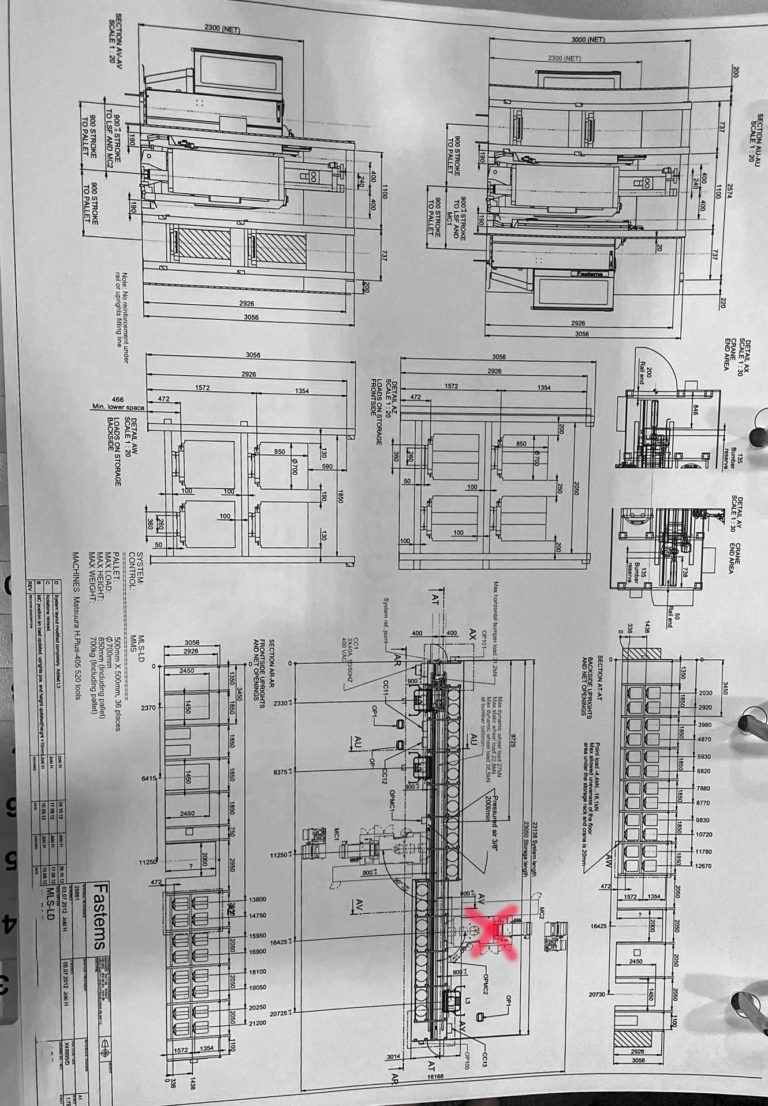

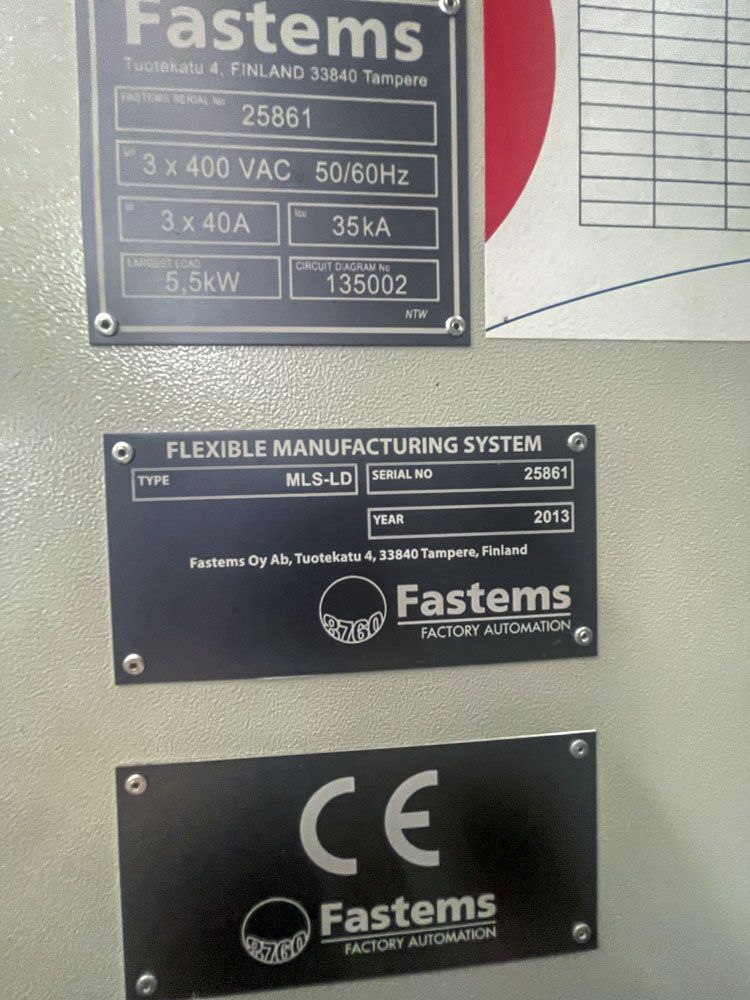

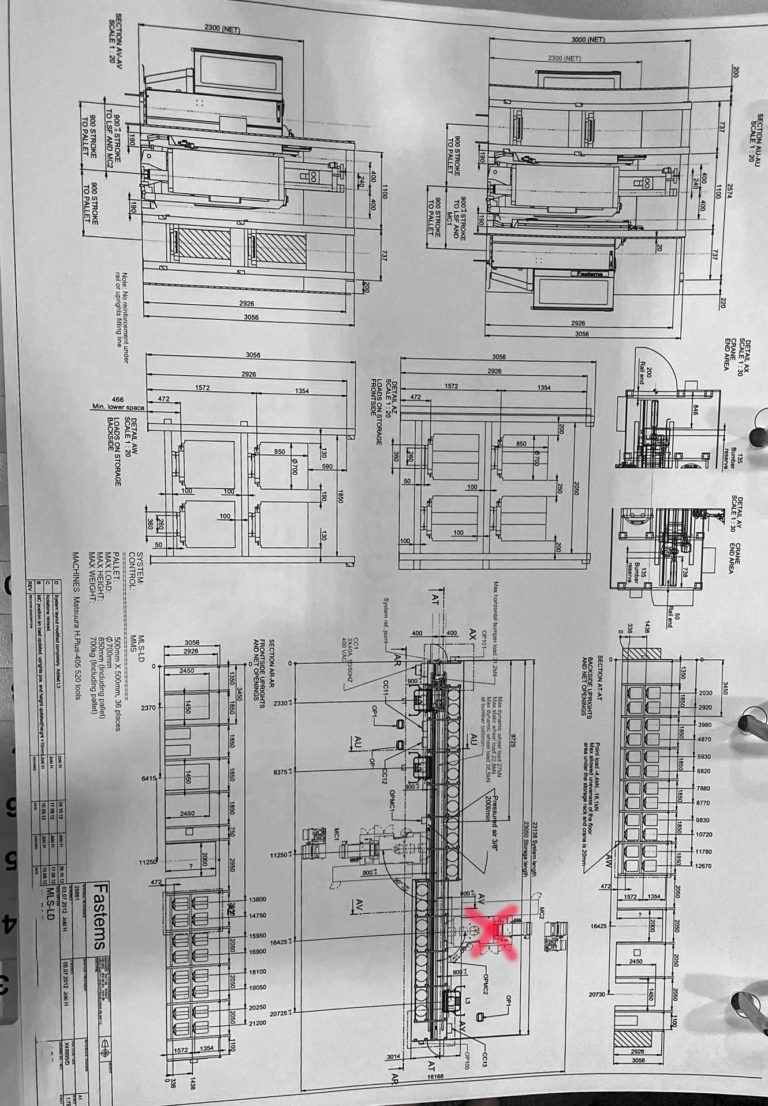

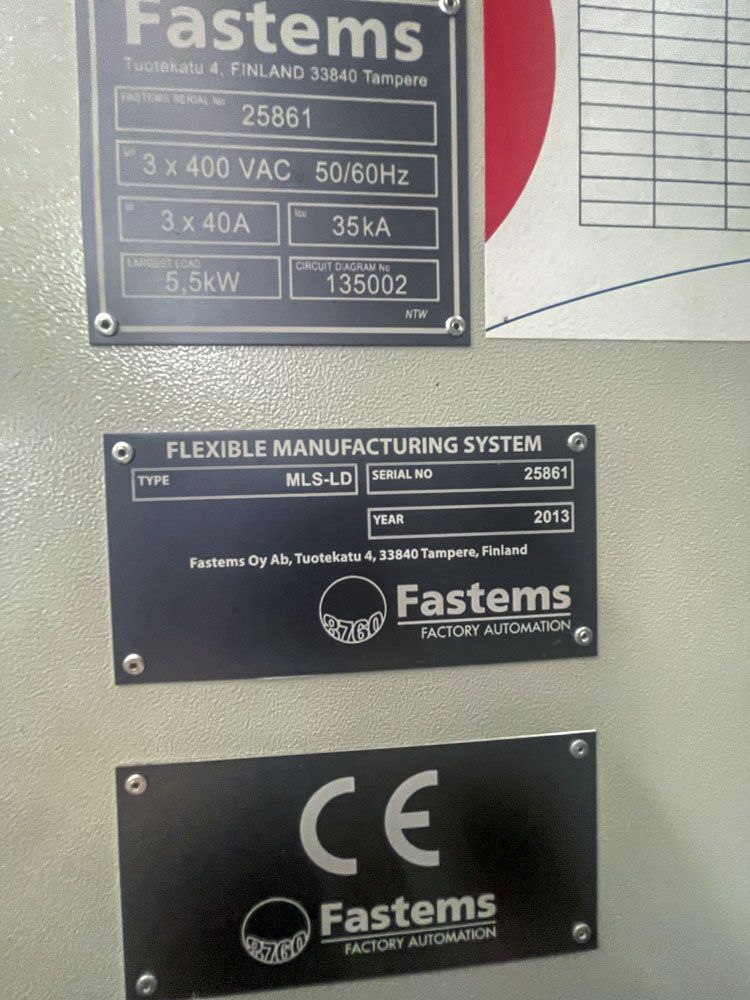

Multi Level System – Light Duty (MLS-LD)

General System Configuration

Control: MMS (Manufacturing Management System)

The system has three loading stations and two connections for machine tools.

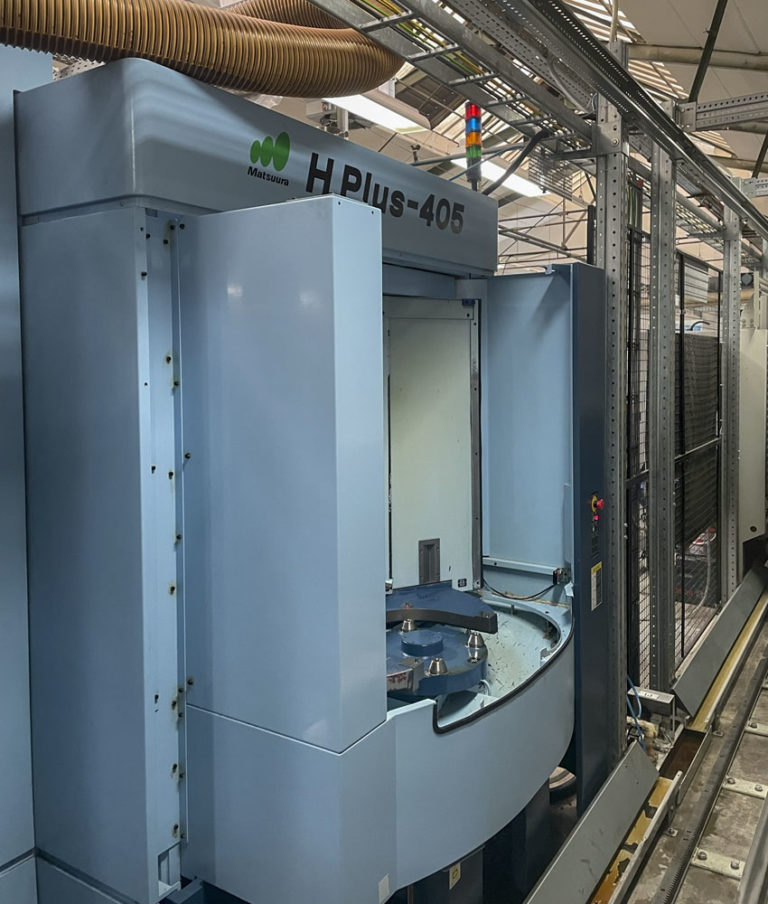

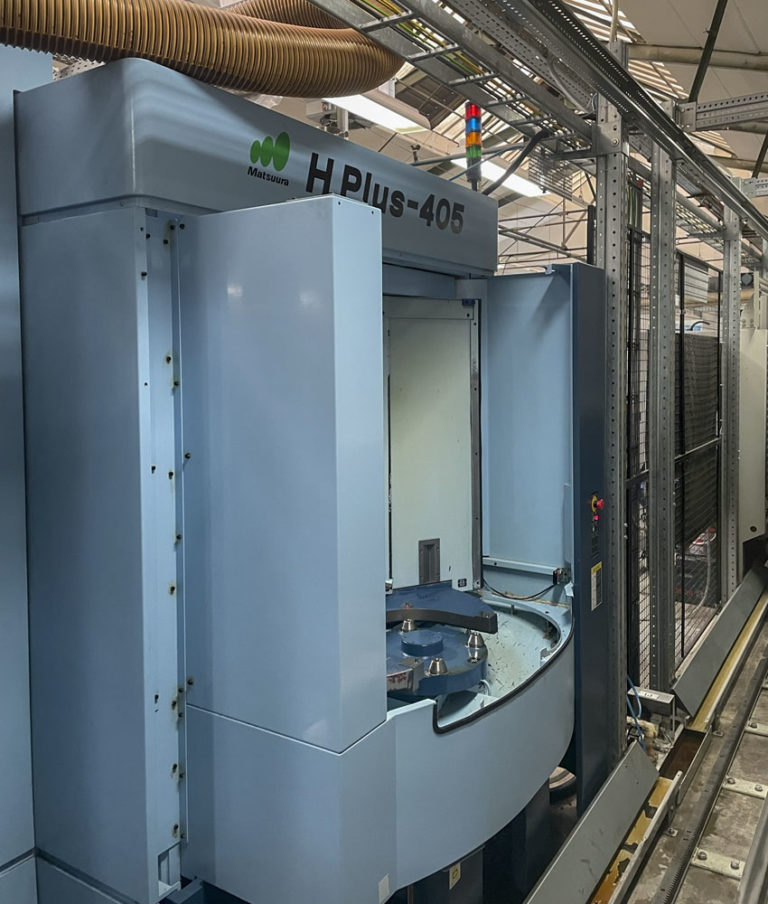

Currently there is a MATSUURA H.Plus-405 machine connected to the system, with the second machine bay free.

Pallet storage

Number of pallets: 36

Pallet dimensions mm: 500×500

Minimum working height of the load handling device: 486 mm

Number of storage levels: 2 levels

Max. workpiece size (D x H) mm: ø700×850 (included pallet)

Maximum weight kg: 700 (included pallet)

Transport capacity: approx. 82 single transfers/hour

Length of the system: approx. 21 meters

Height of the system: approx. 3.2 meters

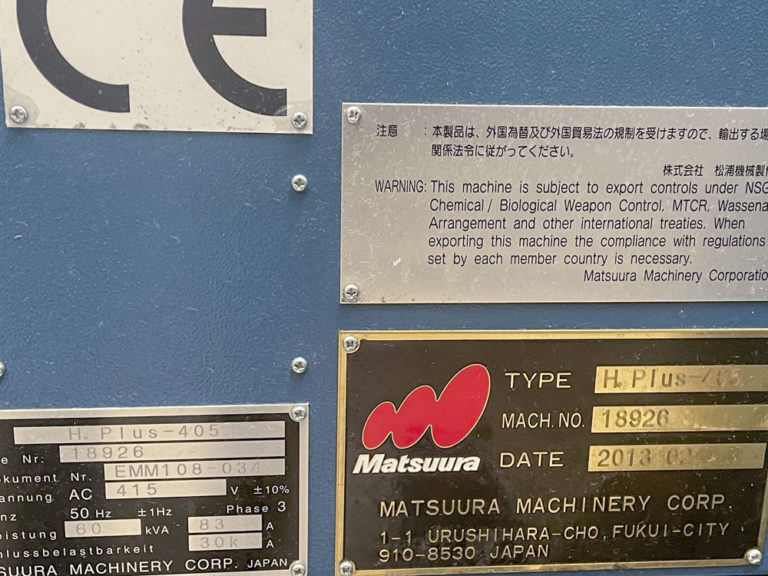

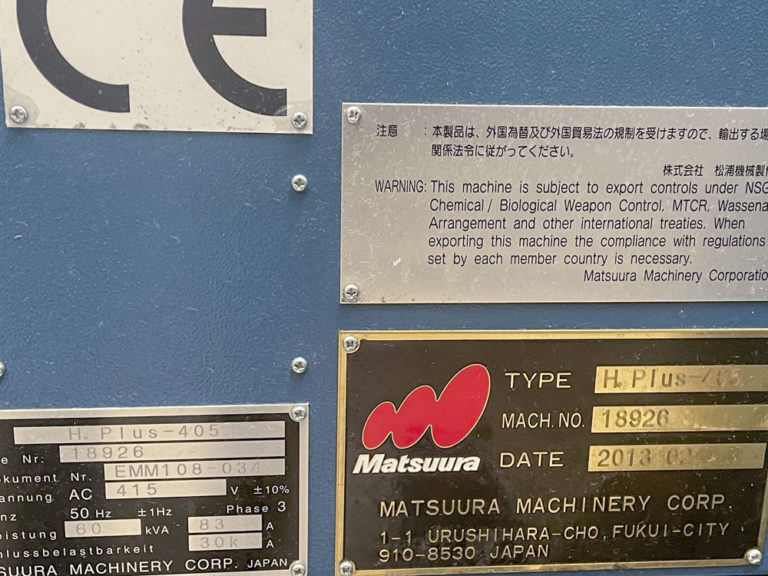

Machine center: MATSUURA MAXIA H.PLUS-405 (CNC0485)

CNC controller: SIEMENS 840Di

Axes

X-axis travel mm: 660

Y-axis travel mm: 660

Z-axis travel mm: 660

B-axis degrees: 360º (0,001º)

Feed rates m/min: 60

Rapid traverse m/min: 60

Spindle

Spindle speed rpm: 40 – 12.000

Cooling

Cooling through the Spindle Center bar: 70

Tank capacity: 1.400

Tool system

Tool holder: SK-40 Big+

Tool magazine slots: 360

Max. Tool Diameter

With free neighboring places mm: ø150

With occupied neighboring places mm: ø80

Max. Tool Length mm: 350

Max tool weight kg: 10

Equipment

Electronic Handwheel

Chip conveyor

Infrared probe (RENISHAW OMP60)

Rotating inspection window

Rinsing gun

blowing air through spindle center

Signal lamp

High pressure pump

Tool breakage probe

Mist collector

Blowing air outside the spindle

Direct measuring system XYZ

Working coordinate systems (99)

Precision NC rotary table, rapid traverse, and feed rate 100 1/min incl. direct measuring system

董雁冰

CEO

Cillian Weber

CEO

Matsuura

Germany

2013

Matsuura

Germany

2013

Multi Level System – Light Duty (MLS-LD)

General System Configuration

Control: MMS (Manufacturing Management System)

The system has three loading stations and two connections for machine tools.

Currently there is a MATSUURA H.Plus-405 machine connected to the system, with the second machine bay free.

Pallet storage

Number of pallets: 36

Pallet dimensions mm: 500×500

Minimum working height of the load handling device: 486 mm

Number of storage levels: 2 levels

Max. workpiece size (D x H) mm: ø700×850 (included pallet)

Maximum weight kg: 700 (included pallet)

Transport capacity: approx. 82 single transfers/hour

Length of the system: approx. 21 meters

Height of the system: approx. 3.2 meters

Machine center: MATSUURA MAXIA H.PLUS-405 (CNC0485)

CNC controller: SIEMENS 840Di

Axes

X-axis travel mm: 660

Y-axis travel mm: 660

Z-axis travel mm: 660

B-axis degrees: 360º (0,001º)

Feed rates m/min: 60

Rapid traverse m/min: 60

Spindle

Spindle speed rpm: 40 – 12.000

Cooling

Cooling through the Spindle Center bar: 70

Tank capacity: 1.400

Tool system

Tool holder: SK-40 Big+

Tool magazine slots: 360

Max. Tool Diameter

With free neighboring places mm: ø150

With occupied neighboring places mm: ø80

Max. Tool Length mm: 350

Max tool weight kg: 10

Equipment

Electronic Handwheel

Chip conveyor

Infrared probe (RENISHAW OMP60)

Rotating inspection window

Rinsing gun

blowing air through spindle center

Signal lamp

High pressure pump

Tool breakage probe

Mist collector

Blowing air outside the spindle

Direct measuring system XYZ

Working coordinate systems (99)

Precision NC rotary table, rapid traverse, and feed rate 100 1/min incl. direct measuring system

Request your quote

Sales Department

Besides, we not only have the best prices in the market, we also offer you the possibility of financing access to top quality machines at an affordable cost.

It is about important investments and that is why we are clear with a 100% safe machinery purchase and sales process, in order that you have all the necessary information to buy such a product.

To avoid that you have to travel, we take care of the transport and shipment of the purchase to your place of work. We collaborate with companies specialised in this type of orders and we can both, sell at source and turnkey.

董雁冰

CEO

Cillian Weber

CEO