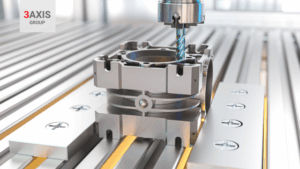

The world of CNC lathe machines is undergoing a remarkable transformation. As industries continue to demand greater precision, efficiency, and adaptability, the technologies powering CNC machines are advancing at an unprecedented pace. In this article, we will explore the future of CNC lathe machines and how these innovations are shaping the manufacturing landscape.

Discover the future of CNC lathe machines

CNC lathe machines have long been at the forefront of precision engineering. These versatile tools are pivotal in industries ranging from aerospace and automotive to medical and energy. However, as the demands on manufacturing processes evolve, so must the capabilities of CNC machines.

The future of CNC lathe machines promises to bring groundbreaking developments that will revolutionize the way industries operate. Let’s explore the key areas where these machines are set to make leaps forward.

Advanced Automation Capabilities

Automation has been a driving force behind the efficiency of CNC machine lathes, and this trend is only expected to accelerate. In the coming years, we can anticipate:

- Self-monitoring systems: CNC lathe machines equipped with sensors and IoT capabilities will enable real-time monitoring of operations, ensuring smoother workflows and reducing downtime.

- Lights-out manufacturing: Fully automated CNC lathe machines capable of operating 24/7 without human intervention will become more commonplace, offering unparalleled productivity.

- Collaborative robotics: The integration of cobots (collaborative robots) with CNC machines will allow for seamless human-machine collaboration, improving safety and efficiency.

Improved User Interfaces and Accessibility

One of the most exciting advancements in CNC lathe technology is the evolution of user interfaces. As these machines become more sophisticated, manufacturers are making them more user-friendly:

- Intuitive controls: Modern CNC lathe machines are adopting touchscreen interfaces and simplified programming languages to reduce the learning curve for operators.

- Remote operation: With the advent of cloud computing, operators can now control CNC machine lathes remotely, enabling greater flexibility and convenience.

- Enhanced training tools: Virtual reality (VR) and augmented reality (AR) are being employed to provide immersive training experiences for operators, reducing errors and improving productivity.

Integration of Artificial Intelligence

Artificial intelligence (AI) is poised to be a game-changer for CNC lathe machines. The integration of AI will lead to smarter and more efficient manufacturing processes:

- Predictive maintenance: AI algorithms will analyze machine data to predict potential breakdowns, minimizing downtime and extending machine lifespan.

- Adaptive machining: CNC lathe machines will use AI to adjust cutting parameters in real time, optimizing performance and ensuring consistent quality.

- Enhanced design capabilities: AI-driven software will allow operators to create more complex and precise designs, pushing the boundaries of what CNC machines can achieve.

Enhanced Precision and Accuracy

Precision has always been a hallmark of CNC lathe machines, and future developments will take this to new heights:

- Nano-level machining: Advances in tooling and control systems will enable CNC lathe machines to achieve unprecedented levels of precision, essential for industries like medical device manufacturing and electronics.

- Error reduction: Improved sensors and feedback systems will minimize deviations, ensuring that every product meets exact specifications.

- Real-time quality control: CNC machine lathes will incorporate integrated quality control systems, allowing for instant detection and correction of defects.

Customization and Flexibility

The manufacturing industry is moving towards greater customization, and CNC lathe machines are adapting to meet this demand:

- Multi-axis capabilities: The addition of more axes to CNC machine lathes will allow for complex geometries to be machined in a single setup, reducing time and cost.

- Modular designs: Future CNC lathe machines will feature modular components, enabling quick reconfiguration for different tasks and applications.

- On-demand manufacturing: With advanced software and tooling, CNC lathe machines will excel in producing small batches of highly customized parts, catering to niche markets.

Do you want to know more? You may also be interested in articles such as All You Need to Know About a Milling Machines.

The future of CNC lathe machines is undeniably bright, so we invite you to dazzle with our wide range of CNC lathes.