A central question in modern manufacturing is: What is a CNC machine used for? At 3axis Group, as specialists in industrial machinery, we provide the answer and explain everything you need to know about its use, scope, and how it concretely impacts current production processes.

CNC machines (Computer Numerical Control) have transformed the way parts, objects, and components are produced across multiple industries. Thanks to their precision, efficiency, and automation capabilities, these tools have become a technological standard.

Far from being simple mechanical tools, they serve as a bridge between digital design and physical manufacturing. Their integration into production lines reduces errors, saves materials, and shortens lead times. However, their true value lies in the wide variety of applications they offer.

What is a CNC machine used for in today’s manufacturing landscape?

In today’s industrial context, CNC technology is synonymous with productivity, automation, and precision. It is used to control cutting and shaping tools through computer programs that follow three-dimensional digital models.

Thanks to this, the operator can produce complex parts with minimal intervention, reducing production times and ensuring greater process repeatability.

Furthermore, in the era of smart manufacturing and Industry 4.0, CNC machines are essential for integrating processes into larger systems. Their connectivity with design, analysis, and quality control software enables full traceability and better resource management.

This makes them an indispensable investment for companies seeking competitiveness in highly demanding sectors.

Core applications of CNC machines

The versatility of CNC machines allows them to handle multiple tasks within a production environment. They are not limited to a single function and can adapt to different industrial processes based on specific product or client needs.

Precision cutting and shaping

One of the most widespread applications is the cutting and shaping of materials with millimetric precision. This includes metals, plastics, wood, composites, and other industrial materials.

Thanks to numerical control, cuts can follow complex geometries without errors, which is fundamental in sectors where every micrometer counts. Additionally, they allow for working with various thicknesses and densities without compromising the quality of the finish.

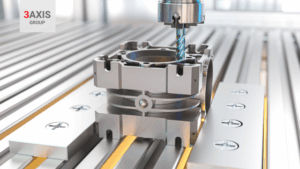

Drilling, milling, and turning operations

CNC drilling and milling enable the creation of cavities, grooves, and flat surfaces with extremely high precision. Meanwhile, CNC turning facilitates the machining of cylindrical parts or components with variable geometric shapes.

These combined operations form the foundation of many industrial machining processes, and their automation allows for consistent repetition with optimized timing.

Mass production of complex parts

Thanks to their ability to operate for long periods without constant supervision, CNC machines are ideal for mass production. They can be programmed to create highly detailed parts without loss of quality between units.

This is essential in industries where uniformity of parts is a priority and where production volumes are high.

Custom prototyping and rapid tooling

The speed and adaptability of CNC machines also make them ideal for creating prototypes or specialized tools. During product development stages, they allow designs to be tested without the need for expensive molds or traditional processes.

This shortens development cycles and improves responsiveness to market needs.

Industries that use CNC machines and why

CNC machines are present in multiple sectors due to their ability to adapt to different materials and processes:

- Aerospace: Extreme precision is required to manufacture structural and mechanical components where any failure could compromise safety.

- Automotive: Enables efficient and precise manufacturing of engine parts, chassis components, molds, and dies at scale.

- Medical and dental: Used to create prosthetics, implants, and customized surgical tools with high precision standards.

- Electronics: Ideal for producing circuit boards, casings, or delicate components with micrometric accuracy.

- Woodworking and furniture: Facilitates complex decorative cuts, carvings, and high-precision assemblies, enhancing both aesthetic and functional quality.

- Energy industry: Applied in the creation of turbines, valves, shafts, and components subjected to high thermal and mechanical demands.

- Defense and security: Allows for the production of critical parts for weaponry, tactical vehicles, and other complex systems with strict tolerance requirements.

Any sector requiring precision, repeatability, and efficiency in component manufacturing can benefit from the integration of CNC machines. What’s essential is their ability to adapt to both artisanal and industrial-scale production.

If you’re interested in articles like this, keep reading How to choose a used CNC machine?.

If you’ve ever asked yourself what is a CNC machine used for?, the answer lies in the wide range of applications, industries, and benefits it brings. At 3Axis Group, we provide specialized CNC machinery solutions tailored to every type of industry. If you’re looking to take a step forward in automation and precision, consider exploring our options.