In today’s fast-paced manufacturing industry, efficiency, precision, and consistency are more important than ever. Traditional methods can no longer keep up with the demands of modern production, where even the smallest error can lead to costly setbacks. This is where CNC machines come in.

By combining advanced automation with unmatched accuracy, CNC technology has become the preferred choice for manufacturers looking to optimize their processes and stay competitive.

What Are CNC Machines?

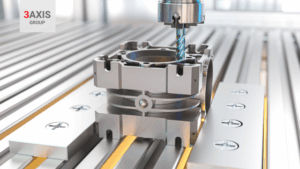

CNC (Computer Numerical Control) machines are computer-operated systems designed to work with a broad range of materials, from wood and plastics to metals and composites.

Their development has revolutionized industrial and creative manufacturing by streamlining processes and allowing the production of complex parts that would be extremely difficult to craft manually.

At the core of these systems is the CNC controller, which translates coded instructions into precise movements across the machine’s axes through motors and drive mechanisms. A typical CNC setup includes essential components such as an input device, a control unit, the machine tool, a drive system, feedback devices in servo-based models, and a monitor for operation oversight.

Why Are CNC Machines Better for Manufacturing?

When comparing modern production methods, CNC machines stand out for their ability to combine speed, accuracy, and automation. Unlike traditional tools, they reduce human error, improve consistency, and handle complex designs with ease. This makes them a superior choice for today’s manufacturing demands. Let’s see some of the main benefits in further detail:

Superior Precision and Consistency

CNC machines deliver a level of precision far beyond what manual machining can achieve. Guided entirely by computer programs, they minimize errors and produce parts with extreme accuracy, which is critical in industries where precision is non-negotiable.

Another key advantage is consistency: once a design is set, the machine can replicate it identically across countless units. This ensures uniform quality, reduces waste, and makes large-scale production both reliable and efficient.

Increased Production Efficiency

CNC manufacturing offers far greater efficiency compared to traditional methods. Once a design is programmed, the machine can produce large batches of identical parts with minimal human input, reducing downtime and accelerating output. Because CNC machines can run continuously, day and night, not only meeting high production demands but also lower labor costs.

This combination of speed, automation, and round-the-clock operation makes them a highly profitable solution for modern manufacturing.

Cost-Effective in the Long Run

Mass production often comes with the challenge of keeping every part identical, even when manufacturing at very high volumes. CNC machines solve this by delivering absolute consistency: each component is produced to match the original specifications, no matter how large the batch.

Since the process is fully automated and guided by preprogrammed instructions, human error is minimized and quality remains constant.

This dependability is especially advantageous for companies that need standardized parts to comply with strict safety requirements. In the long term, the combination of precision and repeatability makes CNC manufacturing a cost-effective choice that boosts efficiency and profitability.

Enhanced Flexibility and Versatility

One of the biggest advantages of CNC machines is their ability to work with a wide range of materials. From metals like aluminum, steel, and titanium to plastics, composites, and even wood, these systems can adapt to the needs of different industries.

Beyond material flexibility, CNC machines are also designed to tackle highly complex shapes and designs. With advanced equipment such as 5-axis machining centers, it is possible to perform accurate cuts from multiple directions, allowing the production of intricate geometries that traditional methods could hardly achieve.

This capability provides manufacturers with greater design freedom and efficiency in production.

Greater Safety for Operators

CNC machining improves workplace safety by reducing the need for direct contact with sharp tools and heavy equipment. Instead of manual handling, operators mainly oversee programming and monitoring, which lowers the chance of accidents. On top of that, modern CNC machines include built-in protections like automatic shutoffs and enclosed systems, further ensuring a safer production environment.

Simplified Prototyping and Design Adjustments

CNC machining makes rapid prototyping faster and more practical. Engineers can turn digital models into physical prototypes quickly, allowing designs to be tested and refined before mass production. This shortens development cycles, lowers costs, and helps companies bring products to market sooner with greater confidence.

Driving the Future of Manufacturing with CNC Precision

At 3Axis, we empower manufacturers with CNC solutions that deliver speed, precision, and consistency at scale. CNC technology minimizes errors, improves safety, and enables complex designs with ease. Our expertise supports efficient, flexible production across industries. We’re your partner in building smarter, faster, and more reliable manufacturing.

If you found this article valuable, we invite you to explore more — including our latest piece on The Future of CNC Lathe Machines.

Discover how 3Axis can optimize your production—explore our CNC solutions today.