In the fast-paced world of precision manufacturing, CNC lathes performnace play a crucial role in achieving efficiency, accuracy, and consistent quality. However, not all machines deliver the same performance, and understanding the key factors that define a high-performing lathe can make all the difference.

This guide breaks down the essential insights every smart buyer should know before investing in CNC lathe technology.

What Is CNC Lathe Performance and Why It Matters

A CNC lathe is a computer-controlled machine that rotates a workpiece while precise cutting tools shape it into the desired form. It merges traditional turning techniques with digital commands (G-code and M-code) to automate production, ensuring high accuracy and repeatability.

This automation allows for the efficient creation of complex, symmetrical parts from even the toughest materials, in both horizontal and vertical setups.

In this article we will explain in further detail why is it important.

Why Is CNC Important for Performance and Productivity?

CNC machining is essential for improving performance and productivity because it automates operations that once required constant manual control.This automation allows machines to run continuously with minimal downtime and human error, ensuring consistent, high-precision results.

Modern CNC systems also reduce setup times through quick-change fixtures and modular tooling, which improves workflow efficiency.

These systems also ensure efficient use of materials and energy, removing only what’s necessary and minimizing waste. Their integration with CAM software and robotics streamlines production lines, while real-time monitoring and precision sensors maintain high accuracy and consistency.

Together, these features boost throughput, cut costs, and create a foundation for continuous improvement and smarter decision-making in every stage of production.

Understanding the CNC Lathe Process Step by Step

Understanding the CNC lathe process step by step helps you see how a digital design becomes a precise, finished part.

From CAD and CAM through material prep, machining, inspection, and finishing, each stage influences accuracy, cost, and lead time. In this article, we are going to help you identify the key actions and decisions that keep your workflow efficient and your results consistent.

From CAD Model to Final Part: Workflow Overview

Every CNC manufacturing project begins with a CAD model, which defines the part’s exact geometry, size, and tolerances, serving as the digital blueprint for production. Once designed, the file is imported into CAM software, where engineers select tools, set cutting paths, and generate G-code, the language that instructs the machine.

Next comes material preparation, where the chosen metal or plastic is cut and fixed into place before machining. The CNC process then transforms the design into a real component through precise milling, turning, or drilling operations, constantly monitored to maintain tight tolerances.

Afterward, each part undergoes quality inspection to verify dimensions, surface finish, and accuracy. If needed, finishing treatments such as anodizing, polishing, or coating are applied to enhance durability and appearance.

Finally, the completed components are cleaned, packed, and delivered, ready for assembly or final use.

Key Components Involved in the CNC Lathe Process

The performance of a CNC lathe depends on the coordination of several essential systems:

- The spindle system is at the core, providing the rotational power that shapes the workpiece. Modern spindles combine high-speed motors with durable bearings to ensure smooth motion, precision, and stability during demanding operations.

- The feed system manages the movement of the cutting tool along multiple axes. Using ball screws, servo motors, and linear guide rails, it converts rotational motion into precise linear positioning, enabling accurate and repeatable machining even at high speeds.

- At the center of it all is the CNC control unit, which acts as the machine’s brain. It interprets the programmed G-code, synchronizes tool and spindle movements, and provides a user-friendly interface that allows operators to monitor and adjust processes in real time. Together, these systems deliver the accuracy, efficiency, and reliability that define CNC lathe performance.

How to Evaluate CNC Lathe Performance Before Buying

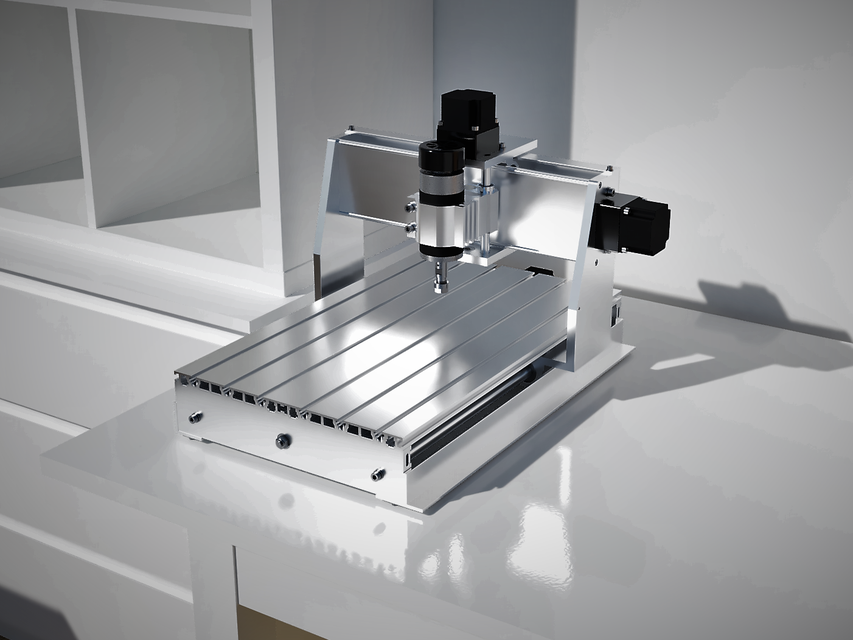

Buying a CNC lathe is a significant investment, so choosing the right one means finding the right balance between performance, cost, and long-term value.

Start by defining the type of parts you plan to produce, lathes excel at round components, while mills are better for flat or angular shapes.Make sure the machine fits your workspace and power setup; compact models with single-phase power are ideal for small shops, while larger units may need reinforced installations.

Also, consider the control software, an intuitive, easy-to-learn interface can drastically reduce setup time and operator errors. Finally, don’t overlook tooling and accessories such as holders, chucks, or automation features, which are key to getting your machine fully operational and scalable from day one.

If you’re interested in learning more, explore this section of our blog for related articles and insights https://3axis-group.com/what-is-a-cnc-machine-used-for/

Selecting the right CNC lathe is about more than just price or brand…it’s about finding a machine that matches your workflow, precision needs, and long-term goals. By understanding how each system works and what truly drives performance, you can invest with confidence.