Máquina vendida

Além disso, não só temos os melhores preços do mercado, como também lhe oferecemos a possibilidade de financiar a compra para facilitar o acesso a máquinas de qualidade superior a um custo acessível.

Trata-se de investimentos importantes e é por isso que estamos certos de que o processo de compra e venda de maquinaria é 100% seguro, para que tenha toda a informação necessária para comprar um produto deste tipo.

Para evitar que tenha de se deslocar, nós encarregamo-nos do transporte e da expedição da compra para o seu local de trabalho. Colaboramos com empresas especializadas neste tipo de encomendas e podemos tanto vender na origem como chave na mão.

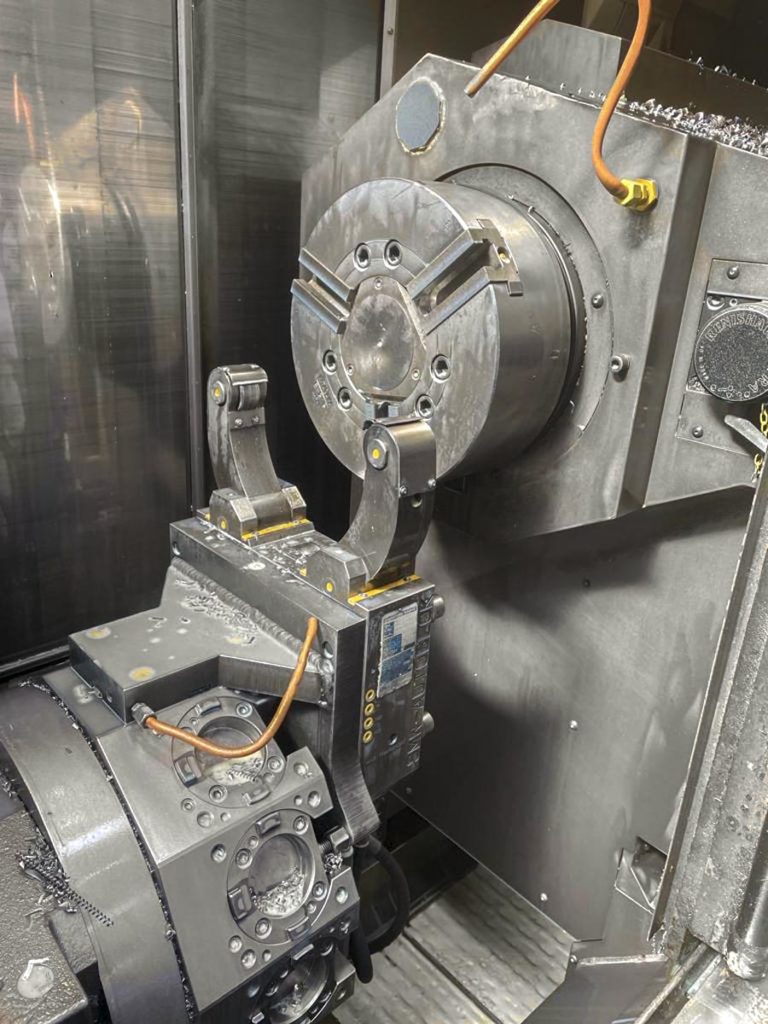

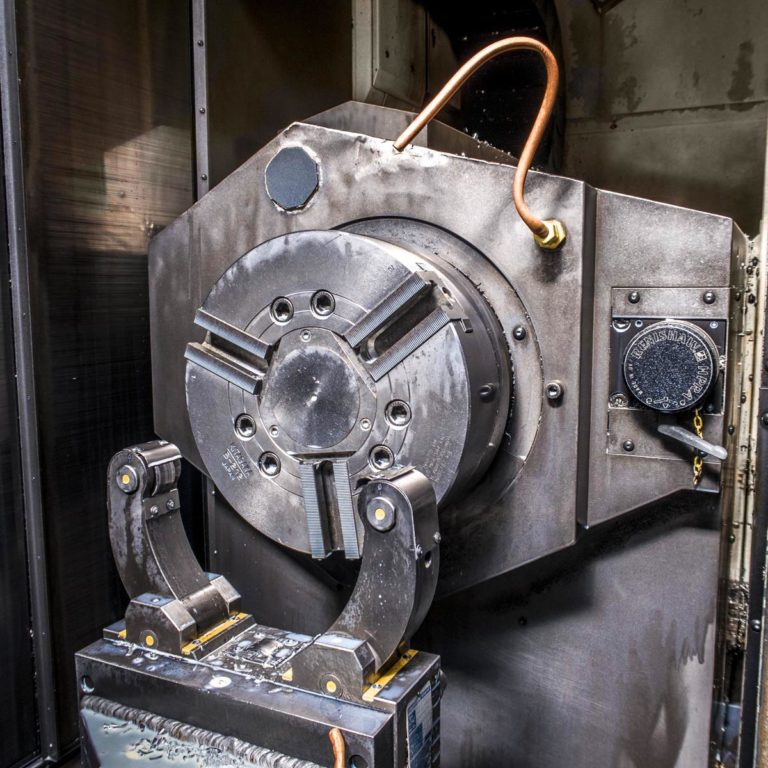

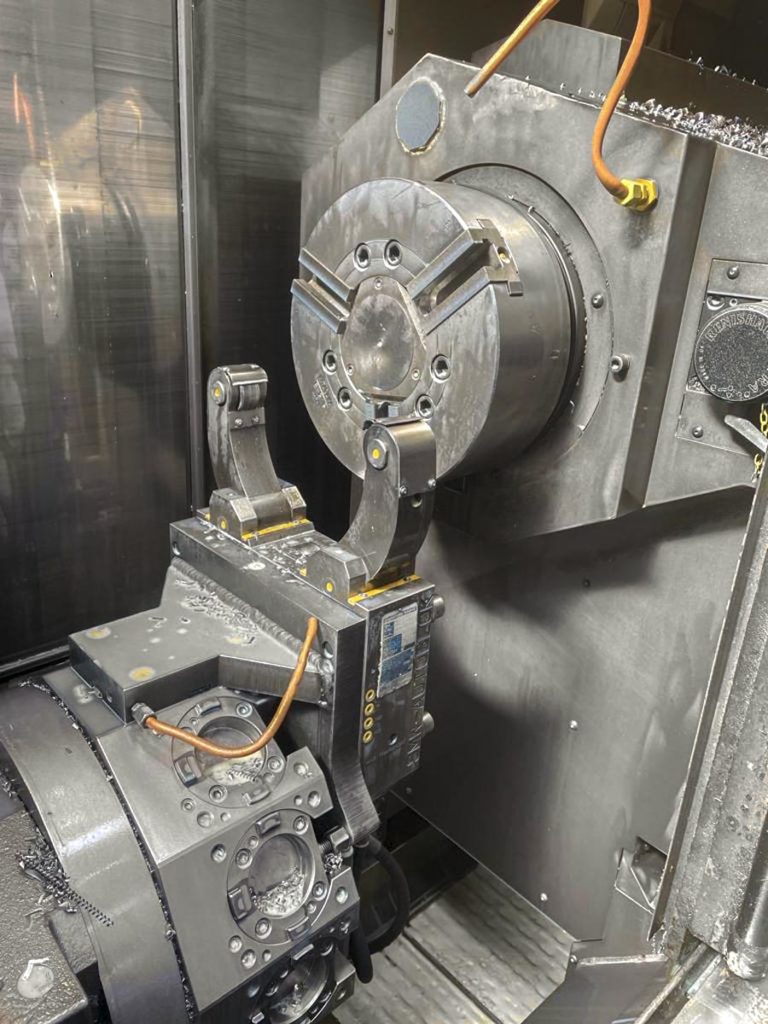

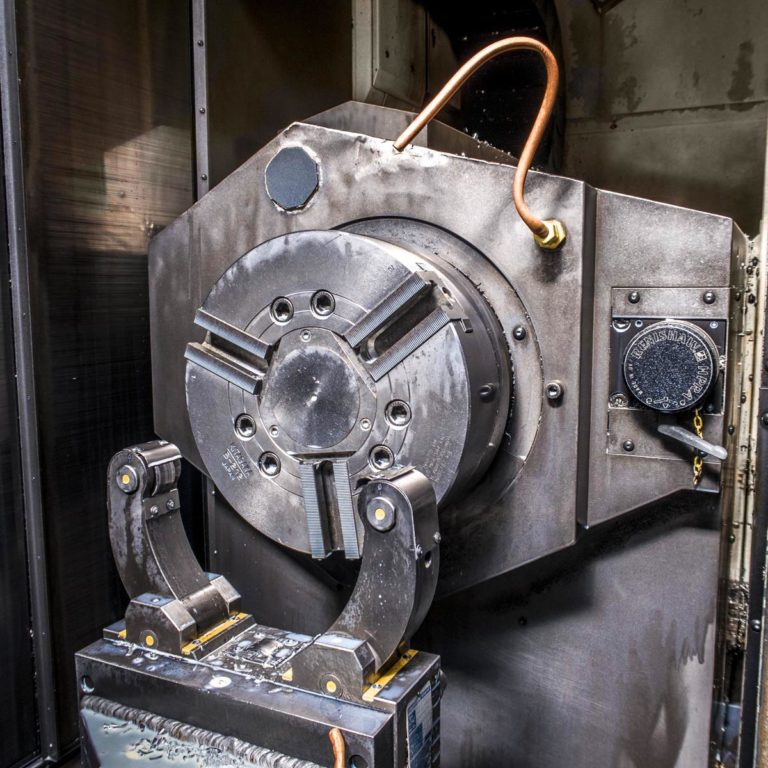

Control: FS-31IA5 (MAPPS 3)

Axes

Turning length mm: 1.542

Turning diameter f. Tool spindle mm: 660

Turning diameter f. lower turret mm: 350

Rapid traverse tool spindle X, Y, Z, m / min: 50,30,50

Rapid traverse lower revolver: X, Z m / min.: 30

Rapid traverse counter spindle m / min.: 30

Tool spindle

Full indexing specifications

X travel mm: 750

Y travel mm: ± 210

Z travel mm: 1,550

B-travel degree: ± 120

Tool system: Capto C6

Tool storage capacity: 100

Speed spindle rpm: 12,000

Drive power spindle kW: 18.5 / 11

Lower turret

X travel mm: 195

Z travel mm: 1.525

Number of tool slots St .: 12

Main spindle

Speed spindle rpm: 4,000

Drive power spindle kW: 22 / 18.5

Through-spindle hole dia. Mm: 91

Chuck type: hollow chuck (12″)

Manufacturer: KITAGAWA

Sub spindle

Speed spindle rpm: 4,000

Drive power spindle kW: 22 / 18.5

Through-spindle hole dia. Mm: 91

Chuck type: hollow chuck (12″)

Manufacturer: KITAGAWA

Equipment

Tool magazine with 100 tool places for Capto C6 for tool diameter up to 70mm, up to 140mm without adjacent tools

MISUBISHI B-axis scale

Chip conveyor

Tool spindle through coolant system

Super high-pressure coolant system

Spindle (spindle 1) chuck air blow

Spindle 2 chuck air blow

Automatic centering steady rest (fixed at turret2)

Signal tower 3 layers (red, white, green)

Chuck foot switch (double) for spindle 1, 2

Renishaw probe pre-installation (probe not included)

Automatic door

Simultaneous 5 axis control

Tool center point control

512 kbyte (1280 m) part program storage

1000 stored programs

Remote communication function (fast data server (100base-tx))

240 tool offset pairs

Tool offset for 5-axis machining

6 work coordinate system pairs

Program restart

Programmable data input

600 custom macro common variables

2 AI contour control

Diameter/radius dynamic exchange

Tool life management

High pressure, with paper band filtration system

Working time hours

Power ON: 48.437

Cutting time head 1: 26.612

Cutting time head 2: 23.996

Basic machine dimensions / weight

Length mm: 6,478

Width mm: 2.980

Height mm: 3,264

Weight kg: 25,600

董雁冰

CEO

Cillian Weber

CEO

Mori Seiki

Germany

2007

Mori Seiki

Germany

2007

Control: FS-31IA5 (MAPPS 3)

Axes

Turning length mm: 1.542

Turning diameter f. Tool spindle mm: 660

Turning diameter f. lower turret mm: 350

Rapid traverse tool spindle X, Y, Z, m / min: 50,30,50

Rapid traverse lower revolver: X, Z m / min.: 30

Rapid traverse counter spindle m / min.: 30

Tool spindle

Full indexing specifications

X travel mm: 750

Y travel mm: ± 210

Z travel mm: 1,550

B-travel degree: ± 120

Tool system: Capto C6

Tool storage capacity: 100

Speed spindle rpm: 12,000

Drive power spindle kW: 18.5 / 11

Lower turret

X travel mm: 195

Z travel mm: 1.525

Number of tool slots St .: 12

Main spindle

Speed spindle rpm: 4,000

Drive power spindle kW: 22 / 18.5

Through-spindle hole dia. Mm: 91

Chuck type: hollow chuck (12″)

Manufacturer: KITAGAWA

Sub spindle

Speed spindle rpm: 4,000

Drive power spindle kW: 22 / 18.5

Through-spindle hole dia. Mm: 91

Chuck type: hollow chuck (12″)

Manufacturer: KITAGAWA

Equipment

Tool magazine with 100 tool places for Capto C6 for tool diameter up to 70mm, up to 140mm without adjacent tools

MISUBISHI B-axis scale

Chip conveyor

Tool spindle through coolant system

Super high-pressure coolant system

Spindle (spindle 1) chuck air blow

Spindle 2 chuck air blow

Automatic centering steady rest (fixed at turret2)

Signal tower 3 layers (red, white, green)

Chuck foot switch (double) for spindle 1, 2

Renishaw probe pre-installation (probe not included)

Automatic door

Simultaneous 5 axis control

Tool center point control

512 kbyte (1280 m) part program storage

1000 stored programs

Remote communication function (fast data server (100base-tx))

240 tool offset pairs

Tool offset for 5-axis machining

6 work coordinate system pairs

Program restart

Programmable data input

600 custom macro common variables

2 AI contour control

Diameter/radius dynamic exchange

Tool life management

High pressure, with paper band filtration system

Working time hours

Power ON: 48.437

Cutting time head 1: 26.612

Cutting time head 2: 23.996

Basic machine dimensions / weight

Length mm: 6,478

Width mm: 2.980

Height mm: 3,264

Weight kg: 25,600

Além disso, não só temos os melhores preços do mercado, como também lhe oferecemos a possibilidade de financiar o acesso a máquinas de qualidade superior a um custo acessível.

Trata-se de investimentos importantes e é por isso que somos claros com um processo de compra e venda de máquinas 100% seguro, para que tenha toda a informação necessária para comprar um produto deste tipo.

Para evitar que tenha de se deslocar, nós encarregamo-nos do transporte e da expedição da compra para o seu local de trabalho. Colaboramos com empresas especializadas neste tipo de encomendas e podemos tanto vender na origem como chave na mão.

董雁冰

CEO

Cillian Weber

CEO

3Axis Group

Fortuna Park Flinger Broich 203,

Halle 7-K, 40235 Düsseldorf, Germany

Fernando Mainar

+49 160 967 877 36

fernando@3axis-group.com

Industrial machines

About 3Axis Group