Machine sold

Besides, we not only have the best prices in the market, we also offer you the possibility of financing the purchase to facilitate access to top quality machines at an affordable cost.

It is about important investments and that is why we are clear with a 100% safe machinery purchase and sale process, in order that you have all the necessary information to buy such a product.

To avoid that you have to travel, we take care of the transport and shipment of the purchase to your place of work. We collaborate with companies specialised in this type of orders and we can both, sell at source or turnkey.

Control: FS-31IA5 (MAPPS 3)

Axes

Turning length mm: 1.542

Turning diameter f. Tool spindle mm: 660

Turning diameter f. lower turret mm: 350

Rapid traverse tool spindle X, Y, Z, m / min: 50,30,50

Rapid traverse lower revolver: X, Z m / min.: 30

Rapid traverse counter spindle m / min.: 30

Tool spindle

Full indexing specifications

X travel mm: 750

Y travel mm: ± 210

Z travel mm: 1,550

B-travel degree: ± 120

Tool system: Capto C6

Tool storage capacity: 100

Speed spindle rpm: 12,000

Drive power spindle kW: 18.5 / 11

Lower turret

X travel mm: 195

Z travel mm: 1.525

Number of tool slots St .: 12

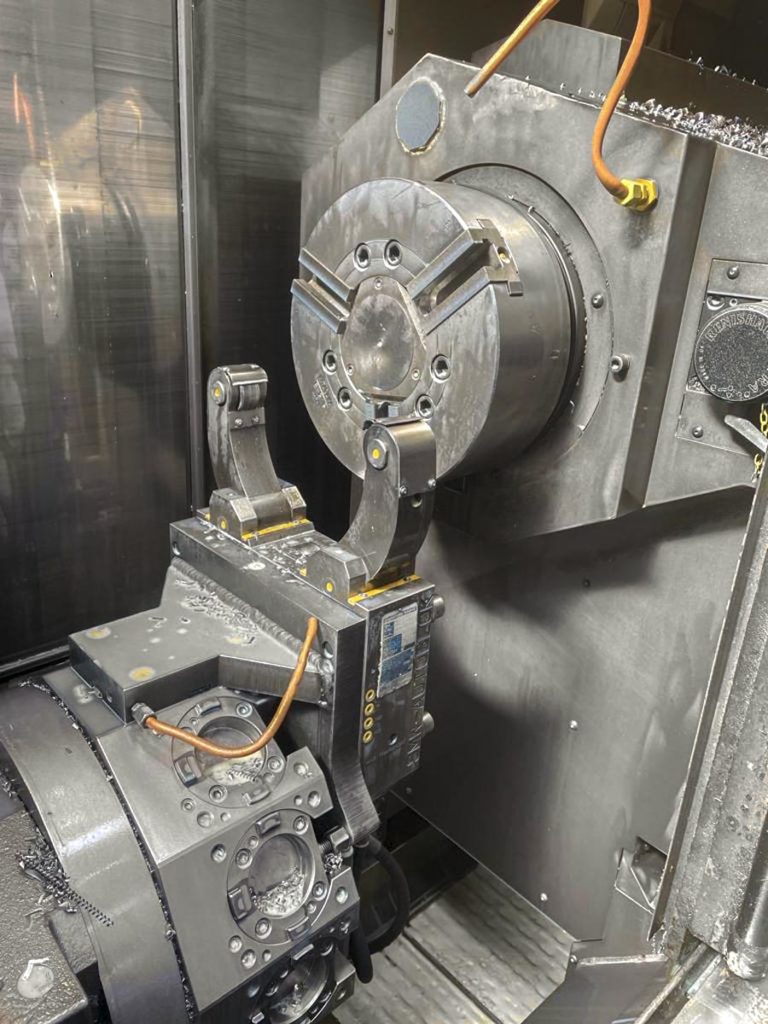

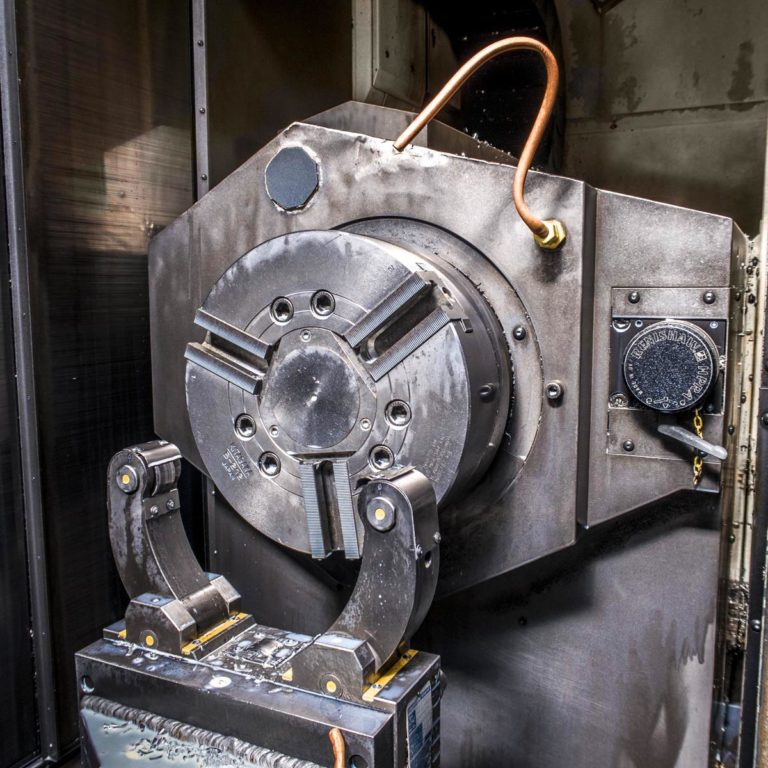

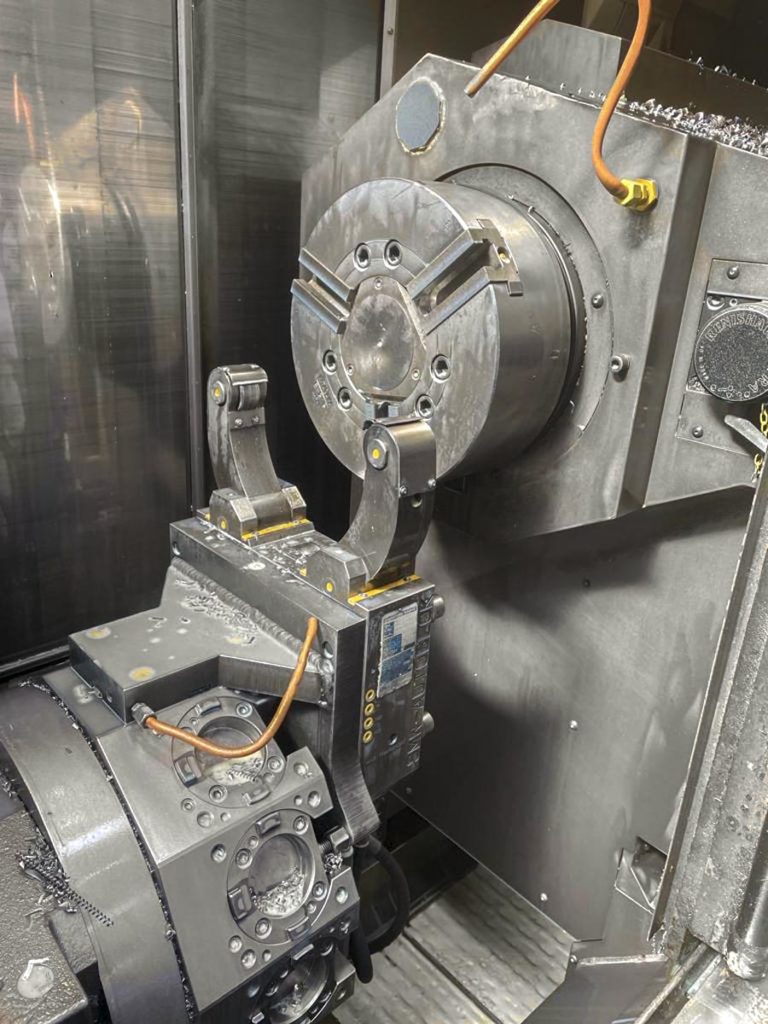

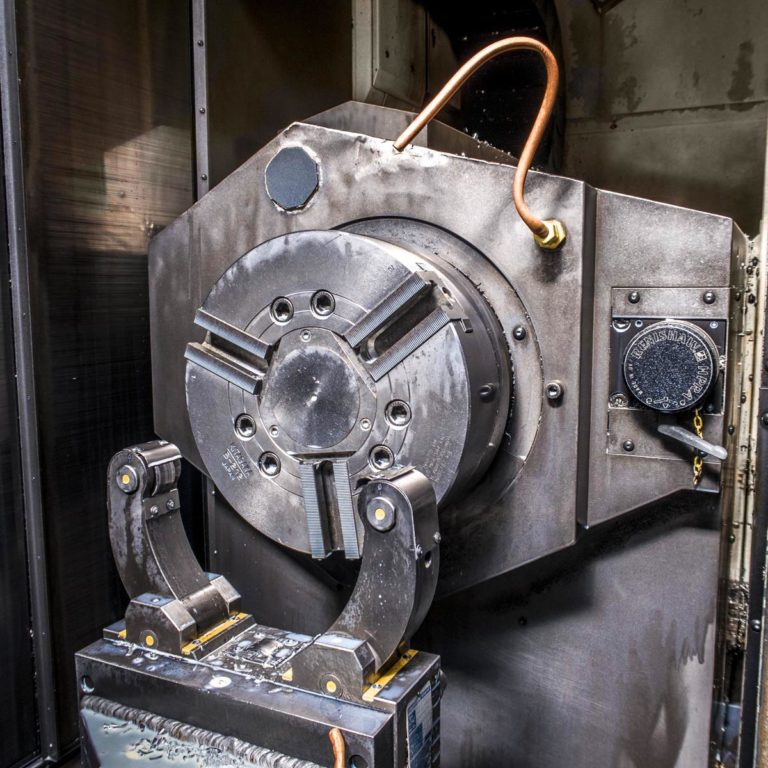

Main spindle

Speed spindle rpm: 4,000

Drive power spindle kW: 22 / 18.5

Through-spindle hole dia. Mm: 91

Chuck type: hollow chuck (12″)

Manufacturer: KITAGAWA

Sub spindle

Speed spindle rpm: 4,000

Drive power spindle kW: 22 / 18.5

Through-spindle hole dia. Mm: 91

Chuck type: hollow chuck (12″)

Manufacturer: KITAGAWA

Equipment

Tool magazine with 100 tool places for Capto C6 for tool diameter up to 70mm, up to 140mm without adjacent tools

MISUBISHI B-axis scale

Chip conveyor

Tool spindle through coolant system

Super high-pressure coolant system

Spindle (spindle 1) chuck air blow

Spindle 2 chuck air blow

Automatic centering steady rest (fixed at turret2)

Signal tower 3 layers (red, white, green)

Chuck foot switch (double) for spindle 1, 2

Renishaw probe pre-installation (probe not included)

Automatic door

Simultaneous 5 axis control

Tool center point control

512 kbyte (1280 m) part program storage

1000 stored programs

Remote communication function (fast data server (100base-tx))

240 tool offset pairs

Tool offset for 5-axis machining

6 work coordinate system pairs

Program restart

Programmable data input

600 custom macro common variables

2 AI contour control

Diameter/radius dynamic exchange

Tool life management

High pressure, with paper band filtration system

Working time hours

Power ON: 48.437

Cutting time head 1: 26.612

Cutting time head 2: 23.996

Basic machine dimensions / weight

Length mm: 6,478

Width mm: 2.980

Height mm: 3,264

Weight kg: 25,600

董雁冰

CEO

Cillian Weber

CEO

Mori Seiki

Germany

2007

Mori Seiki

Germany

2007

Control: FS-31IA5 (MAPPS 3)

Axes

Turning length mm: 1.542

Turning diameter f. Tool spindle mm: 660

Turning diameter f. lower turret mm: 350

Rapid traverse tool spindle X, Y, Z, m / min: 50,30,50

Rapid traverse lower revolver: X, Z m / min.: 30

Rapid traverse counter spindle m / min.: 30

Tool spindle

Full indexing specifications

X travel mm: 750

Y travel mm: ± 210

Z travel mm: 1,550

B-travel degree: ± 120

Tool system: Capto C6

Tool storage capacity: 100

Speed spindle rpm: 12,000

Drive power spindle kW: 18.5 / 11

Lower turret

X travel mm: 195

Z travel mm: 1.525

Number of tool slots St .: 12

Main spindle

Speed spindle rpm: 4,000

Drive power spindle kW: 22 / 18.5

Through-spindle hole dia. Mm: 91

Chuck type: hollow chuck (12″)

Manufacturer: KITAGAWA

Sub spindle

Speed spindle rpm: 4,000

Drive power spindle kW: 22 / 18.5

Through-spindle hole dia. Mm: 91

Chuck type: hollow chuck (12″)

Manufacturer: KITAGAWA

Equipment

Tool magazine with 100 tool places for Capto C6 for tool diameter up to 70mm, up to 140mm without adjacent tools

MISUBISHI B-axis scale

Chip conveyor

Tool spindle through coolant system

Super high-pressure coolant system

Spindle (spindle 1) chuck air blow

Spindle 2 chuck air blow

Automatic centering steady rest (fixed at turret2)

Signal tower 3 layers (red, white, green)

Chuck foot switch (double) for spindle 1, 2

Renishaw probe pre-installation (probe not included)

Automatic door

Simultaneous 5 axis control

Tool center point control

512 kbyte (1280 m) part program storage

1000 stored programs

Remote communication function (fast data server (100base-tx))

240 tool offset pairs

Tool offset for 5-axis machining

6 work coordinate system pairs

Program restart

Programmable data input

600 custom macro common variables

2 AI contour control

Diameter/radius dynamic exchange

Tool life management

High pressure, with paper band filtration system

Working time hours

Power ON: 48.437

Cutting time head 1: 26.612

Cutting time head 2: 23.996

Basic machine dimensions / weight

Length mm: 6,478

Width mm: 2.980

Height mm: 3,264

Weight kg: 25,600

Besides, we not only have the best prices in the market, we also offer you the possibility of financing access to top quality machines at an affordable cost.

It is about important investments and that is why we are clear with a 100% safe machinery purchase and sales process, in order that you have all the necessary information to buy such a product.

To avoid that you have to travel, we take care of the transport and shipment of the purchase to your place of work. We collaborate with companies specialised in this type of orders and we can both, sell at source and turnkey.

董雁冰

CEO

Cillian Weber

CEO

3Axis Group

Fortuna Park Flinger Broich 203,

Halle 7-K, 40235 Düsseldorf, Germany

Fernando Mainar

+49 160 96787736

fernando@3axis-group.com

Industrial machines

About 3Axis Group